A pressing need

By Andrew Zaske on October 5, 2021

Electric servo-mechanical presses offer increased versatility and production improvement opportunities over hydraulic presses.

Pressing and other actions that apply pressure to an object are used in virtually all industries, from assembly and automotive to material handling, fabrication, tooling and many more. In general, the normal direction of work is vertical orientation, meaning most force is required in only in the downward direction. The upwards force requirement is generally j ust lifting the tooling. Most work is done over a few inches, with total stroke lengths typically under six inches. These processes can be executed in a variety of ways, from manually to fully automatic.

ust lifting the tooling. Most work is done over a few inches, with total stroke lengths typically under six inches. These processes can be executed in a variety of ways, from manually to fully automatic.

There are three basic types of pressing technology in use today, each suited to particular applications.

The oldest pressing technology, the mechanical cam-style flywheel press, dates from the 1800s. The flywheel stores the energy, and a clutch mechanism engages the press arm. Flywheel presses have high accuracy and repeatability. However, their power delivery throughout the power stroke is uneven. This type of design will also generally require twice the calculated force (e.g., if it takes 10 tons to perform a press, a flywheel press must have a 20-ton rating). There is no product changeover capability on a flywheel press, little to no dwell adjustment, and virtually no ability to measure press force. Despite these disadvantages, flywheel presses are ideally suited for punching and forming or other high-speed pressing processes.

Hydraulic presses were introduced in the 1950s. They use pressure transferred through a fluid to apply a force andfeature an electro-hydraulic power unit. On more sophisticated systems, a controller adjusts stroke, speed and force. Yet a hydraulic press struggles to achieve the high cycling speeds and parts quality of a flywheel-driven mechanical system. The advantage of a hydraulic press is its greater versatility with variable stroke length, pressure and speeds. They are ideal for injection molding, metal forming and powder compacting.

The newest technology is the electric servo-mechanical press. It offers all the versatility of a hydraulic press, with production speeds close to flywheel presses. Press stroke, position and speeds are easily programmed for accuracy and repeatability. Pressing forces are as high as 40,000 lbf (178 kN) at the end of the force extension, making servo-mechanical presses ideal for pressing, riveting, clinching and most of the applications typically performed by flywheel or hydraulic presses.

Application examples

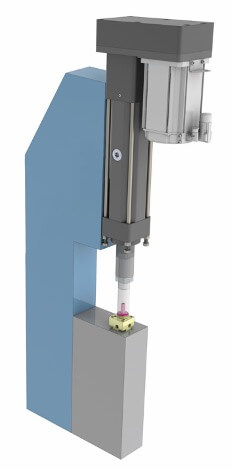

Cosmetic Powder Forming, Pressing & Packing

A manufacturer had used hydraulics to press/form and package makeup and other cosmetics. Each part of the process had issues regarding position control, feedback, speed, accuracy and repeatability. The machines required constant cleaning due to hydraulic fluids leaking from the hoses and pumps. The main pump and reservoir of the hydraulic system was large and took up considerable floor space in the production area. Changing to different cosmetic lines or product mixtures was a time consuming operation.

To improve speed, accuracy and repeatability, the manufacturer replaced the hydraulic cylinder with a Tolomatic RSA50 rod-style actuator with RP (reverse parallel motor mount). The servo motor/drive system selected was able to keep each product line requirement recorded/available and supplied a flexible controls platform for the operators to make changes on the fly during production.

As a result, the manufacturer removed messy hydraulic fluids, hoses and pumps and the hydraulic main pump and reservoir, which freed up floor space. Switching to an electric system kept the project within budget while significantly reducing product scrap.

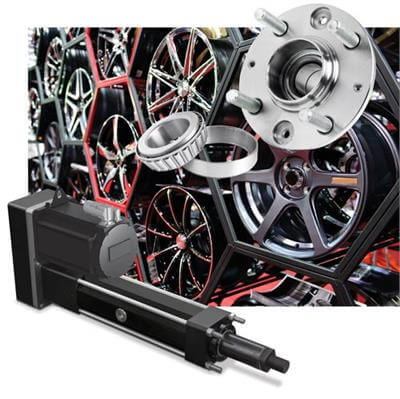

Wheel Bearing Press

An OEM of wheel bearing presses for the automotive market wanted to replace hydraulic cylinders to improve process control, reduce energy consumption and eliminate hydraulic fluid leakage. Although the hydraulic system provided the necessary force during the changeover from one wheel size to another, the machine operators had to make multiple adjustments to fine tune performance. Each changeover resulted in lost production time and rework. In addition, the hydraulic power unit had to run continuously which consumed large amounts of energy.

To provide consistent, repeatable force (75 kN/17,000 lbf), the OEM replaced the hydraulic cylinders with RSX extreme force electric actuators. The servo-controlled RSX actuator allowed for quick and easy changeover procedures to accommodate any wheel size. The 80% efficiency of the servo system was significantly higher than the 40-50% efficiency of the previous hydraulic system, which allowed for substantial energy savings.

Switching to a high-force electric actuator gave the OEM consistent force performance for better process control and increased system efficiency for significant utility cost savings.

Learn more about Tolomatic’s press model extreme-force electric actuator.

Learn more about converting hydraulic cylinders to high-force electric systems. Download our e-book.

Do you have a pressing need? Tolomatic engineers are happy to discuss your application. Contact one today!

For further reading:

Ask an Engineer

Ask an Engineer