Electric Actuator FAQs

This section is for frequently asked questions regarding Tolomatic’s electric motion control products. If you have a question not covered here, feel free to reach us at 1-800-328-2174 or help@tolomatic.com

What is the maximum stroke length of Tolomatic electric actuators?

Tolomatic actuators are offered at configurable stroke lengths to fit your machine design. Rod style actuators up to 60 in. (1524 mm), Rodless screw-drive are offered with strokes up to 120 in. (3048 mm) and belt-drive actuators up to 292 in. (7417 mm). Max stroke lengths will vary and depend on the actuator series, screw technology, and options selection.

Can you use third party motors on the Tolomatic electric actuators?

Tolomatic’s Your Motor Here® program provides hundreds of standard motor mounts for many different manufacturers. For the few motors not available in the Your Motor Here® program, the option to do a custom motor mount is always available. Detailed information on the Your Motor Here® can be found here https://www.tolomatic.com/info-center/tools/your-motor-here/

Why is it important to add over travel to the electric actuator stroke?

Electric actuators should never be driven into the end of stroke repeatedly during operation. This repeated impact may shorten life and lead to early unexpected failures. Adding over travel to the actuator stroke ensures that the actuator can run its working stroke without contacting the internal hard stops and bumpers. Tolomatic recommends two inches of additional stroke or “over travel” to allow extra travel for mounting, adjustment and limit switch positioning.

What information is necessary to select an electric actuator?

The basic application information necessary to select an electric actuator is orientation, distance, load, force, move time, cycle rate and environment. As a guide to gathering all of the necessary data please reference the Application Checklist.

Link to Electric Application Check List https://www.tolomatic.com/info-center/resource-details/electric-rod-style-actuator-application-checklist/

How do I select or size an electric actuator?

- Gather required application data. https://www.tolomatic.com/info-center/resource-details/electric-rod-style-actuator-application-checklist/

- Determine which product families are the style suitable. Examples: rod-style or rod-less; industrial or washdown rating; supporting load or force only.

- Use the Tolomatic’s online sizing software to select the best fit electric actuator. http://sizeit.tolomatic.com/ Contact your Tolomatic Application Engineering Team with any questions or to validate your selection. 763-296-7745

What should I look for if the limit switches are not working on an electric actuator?

There are multiple limit switch types available for the electric actuators resulting in varying functionality. They all are triggered by a magnet moving with the actuator. To troubleshoot limit switch operation, a few initial troubleshooting steps should be followed:

- Confirm the wiring diagram for the switch matches the physical circuit.

- Check the voltage range required for the switch and compare to the circuit.

- Confirm the text on the switch is facing out or away from the magnet or the sensing side is facing the magnet.

- Try a different magnet to confirm magnetic field presence.

- Install the switch in a different location or different groove.

What is inertia ratio?

When working with Tolomatic electric actuators, the inertia ratio is referring to the ratio between the actuator’s reflected inertia and the motor’s rotor inertia. The inertia ratio is important for tuning of the motor. If the ratio is too high then overshooting the commanded position could occur. For Tolomatic motors a ratio of 10:1 or less is recommended.

The actuator’s reflected inertia can be calculated using the Tolomatic sizing software and the motor’s rotor inertia is can typically be found as a publish value from the motor manufacturer. The ratio is determined as the actuator reflected inertia divided by the motor rotor inertia.

What is the difference between Add-On Profiles (AOP) and Add-On Instructions (AOI)?

Both Add-On Profiles (AOP) and Add-On Instructions (AOI) are tools used to help integrate Tolomatic’s ACSI integrated servo motor with compatible Allen Bradley PLCs. The AOP contains the EDS file and AOIs to allow the quickest integration. The AOIs are instructions that can be imported into the PLC ladder logic. Some AOIs examples are Start Motion, Home, Incremental Move and Absolute Move.

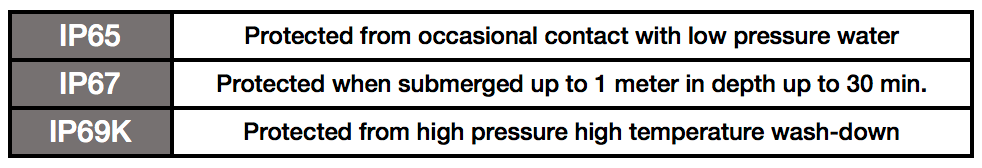

What is meant by ‘static’ IP rating?

The static IP rating has two parts. First, static means the equipment is stopped or not moving. Second, IP or Ingress Protection is rated based on the ability for the equipment to resist particles or liquid from getting inside. All published Tolomatic IP ratings are considered static.

Is there different Tolomatic Motion Interface software for each drive type, ACS servo, ACS stepper and ACSI integrated servo?

Tolomatic Motion Interface software program is a flexible program and is designed for operating all of the Tolomatic ACS(I) drives. The software recognizes the drive type and automatically shows selections for only the connected drive type. The Tolomatic Motion Interface software is available below:

Ask an Engineer

Ask an Engineer