BCS Linear Actuators

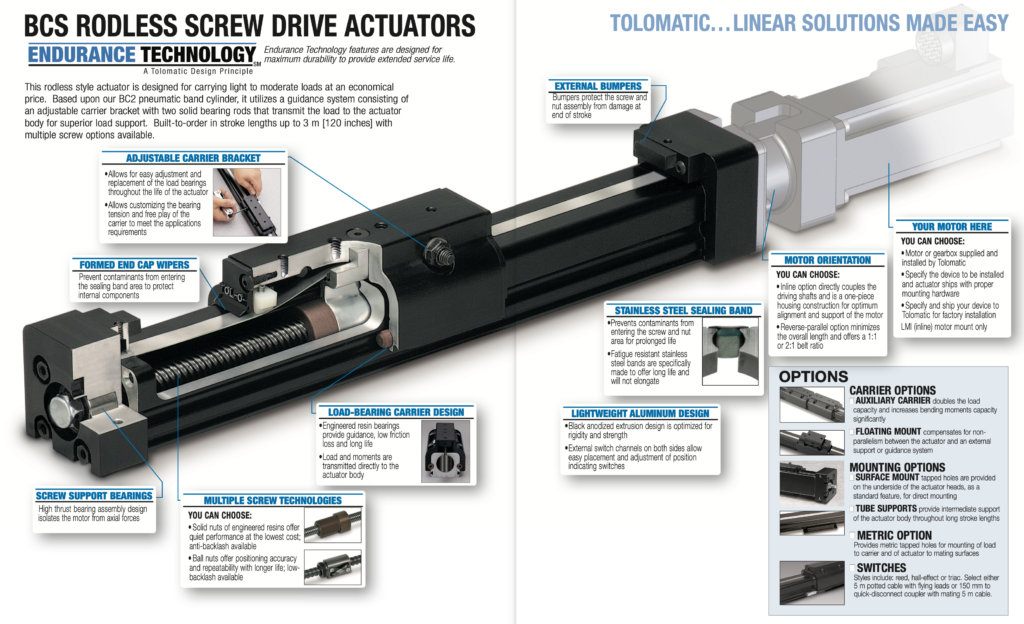

BCS rodless screw actuators are designed for carrying light to moderate loads at a low price.

The BCS rodless screw actuator guidance system uses a patented adjustable carrier bracket that transmits the load to the cylinder body instead of the screw for good tracking, superior load support and controlled minimum friction load. The screw actuator’s patented band retention system forms a tight metal-to-metal seal keeping contaminants out.

- 3 actuator body sizes

- Maximum loads range from 27 to 272 kg (60 to 600 lbs) depending on load carrying selection

- Same envelope size as the B3S Series Screw Drive electric cylinder

- 12 U.S. dimensional screw/nut combinations

- 12 metric screw/nut combinations

- Strokes are available in any incremental length up to 3048 mm (120 in) depending on screw selections

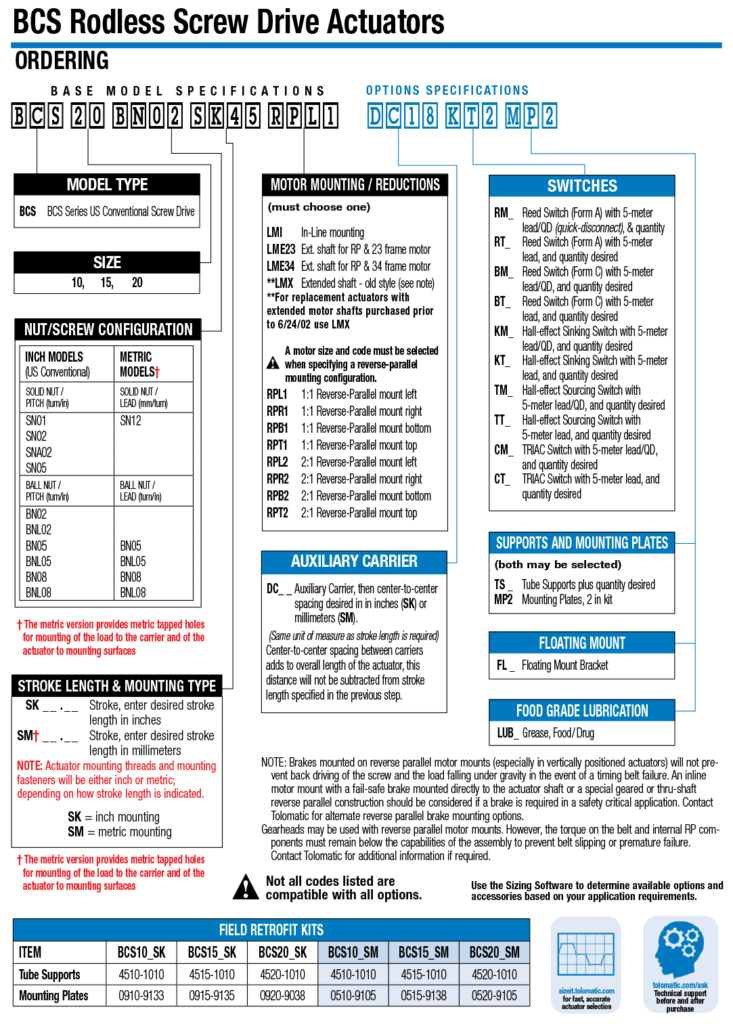

Features & Ordering

Download the BCS Brochure for full details on features

BCS Features

BCS Ordering

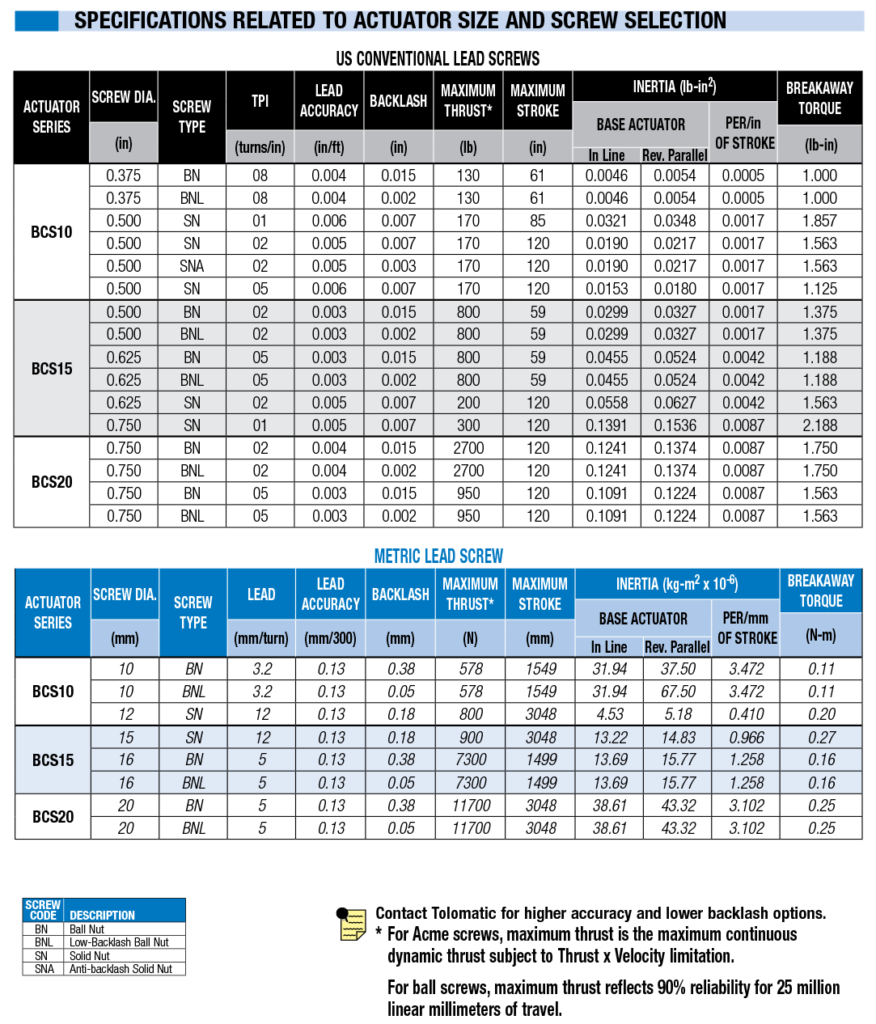

Specifications

BCS Screw Specifications

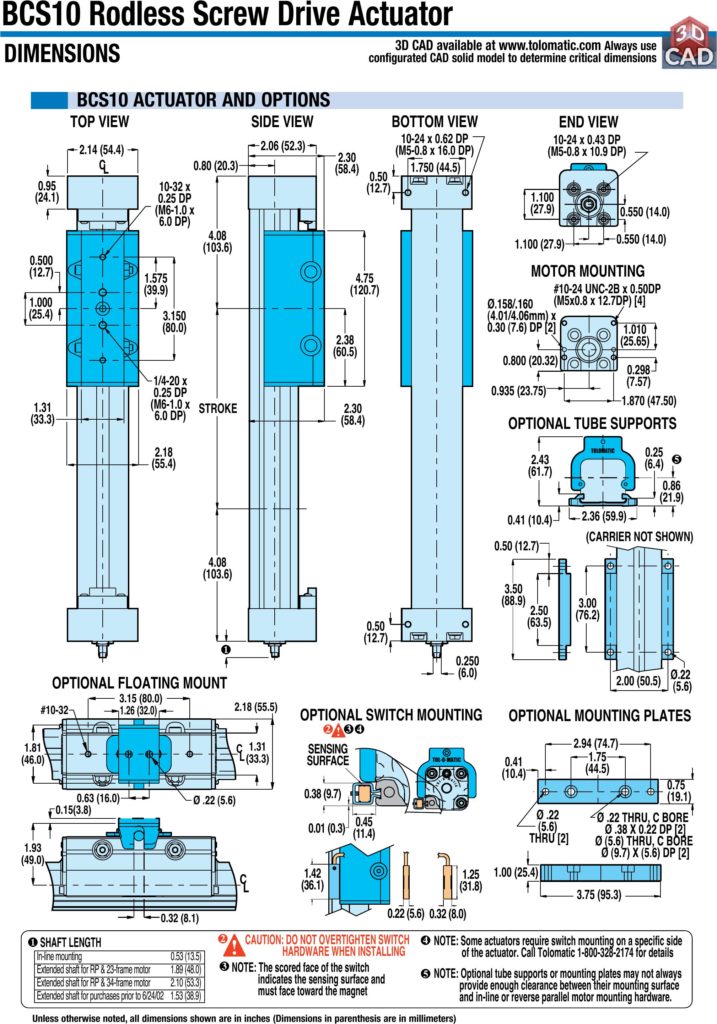

Dimensions

BCS10 Actuator & Options

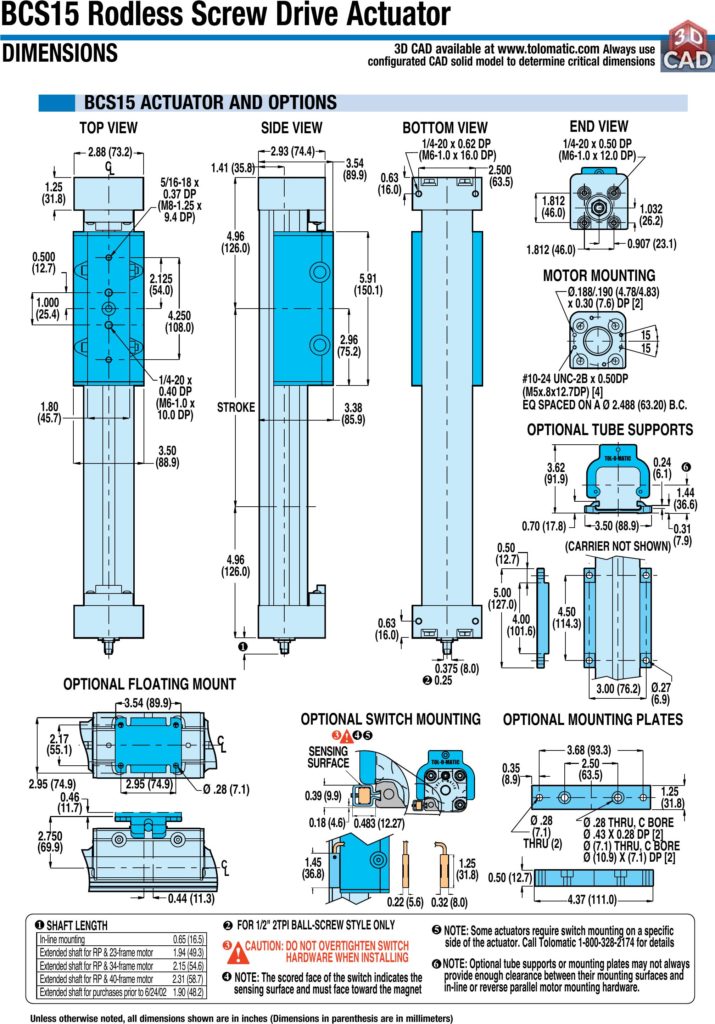

BCS15 Actuator & Options

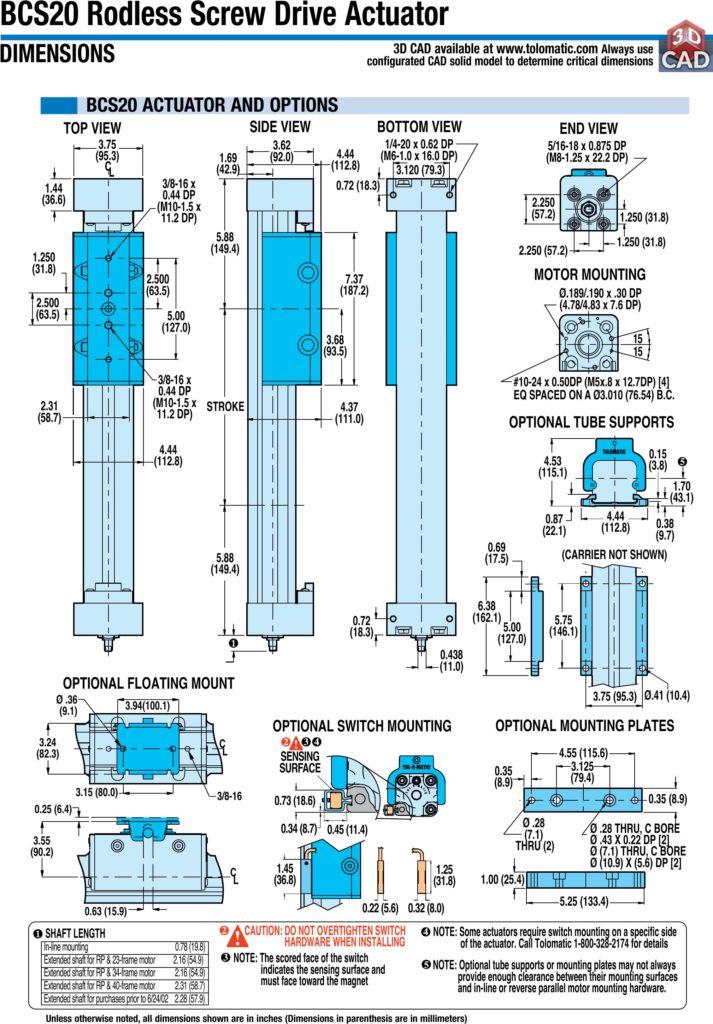

BCS20 Actuator & Options

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

English

Chinese

German

Spanish

Application Checklists

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- BCS Rodless Screw Drive Actuator Catalog

- Automatización de resucitador manual (Bolsa ‘Ambu’) [Spanish - Automation of Manual Resuscitator (‘Ambu’ Bag) (Ventilator)]

- Automation of Manual Resuscitator (‘Ambu’ Bag) (Ventilator)

- Aplicaciounes de la Ind. Automotriz (Auto Appl SP)

- Gantry & Multi-Axis Solutions Brochure

- Soluciones Gantry y Multieje (^ES Gantry brochure)

- OEM Actuator Solutions Brochure

Guides

- Selecting the Optimal Screw Technology

- Actuator Life: How to estimate for ball and roller screw actuators

- INFOGRAPHIC: Accuracy and Repeatability in Linear Actuators

- INFOGRAPHIC: Ten Tips for Specifying Rodless Electric Linear Actuators

- INFOGRAPHIC: Calculating Total Cost of Ownership

- 如何选择 螺杆? 甄选 正确的技术 (Chinese, How to select the right lead screw for an electric actuator)

- Abschnitt: Welches Gewinde? Die richtige Technologie auswählen (German - Which Screw)

- Guide to Third Party Motor Integration

- Switch Reference Guide

Tech Bulletins

Terms & Conditions

White Papers

- Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership

- The truth about actuator life: Screw drive survival

- Select the right linear actuator: Making sense of manufacturer specifications

- Specifying electric rodless actuators: Ten tips for maximizing actuator life and system performance

- Rules of actuator and guide alignment in linear motion systems

- IP ratings and the manufacturing environment: How to apply linear actuators for quality, safety and long service life.

- Minimizing electrical noise in actuator drive systems for maximum reliability and performance

- Screw-driven vs. belt-driven rodless actuators: How to select drive trains for reliability, efficiency and long service life

- Introduction to accuracy and repeatability in linear motion systems

Ask an Engineer

Ask an Engineer