Page Navigation

Electric Pressing Solutions Brochure

Explore Electric Linear Actuators with force capabilities that equal or surpass hydraulic systems. Understand the advantages of electrification for clean, continuous, control in high duty cycle applications. See how Tolomatic can help simplify the design process.

Download Brochure

White Paper:

Unleashing the Capabilities of the Linear Servo Press in Manufacturing

This whitepaper explores how linear and mechanical servo press technologies compare with hydraulic presses and the key design considerations.

Download White Paper

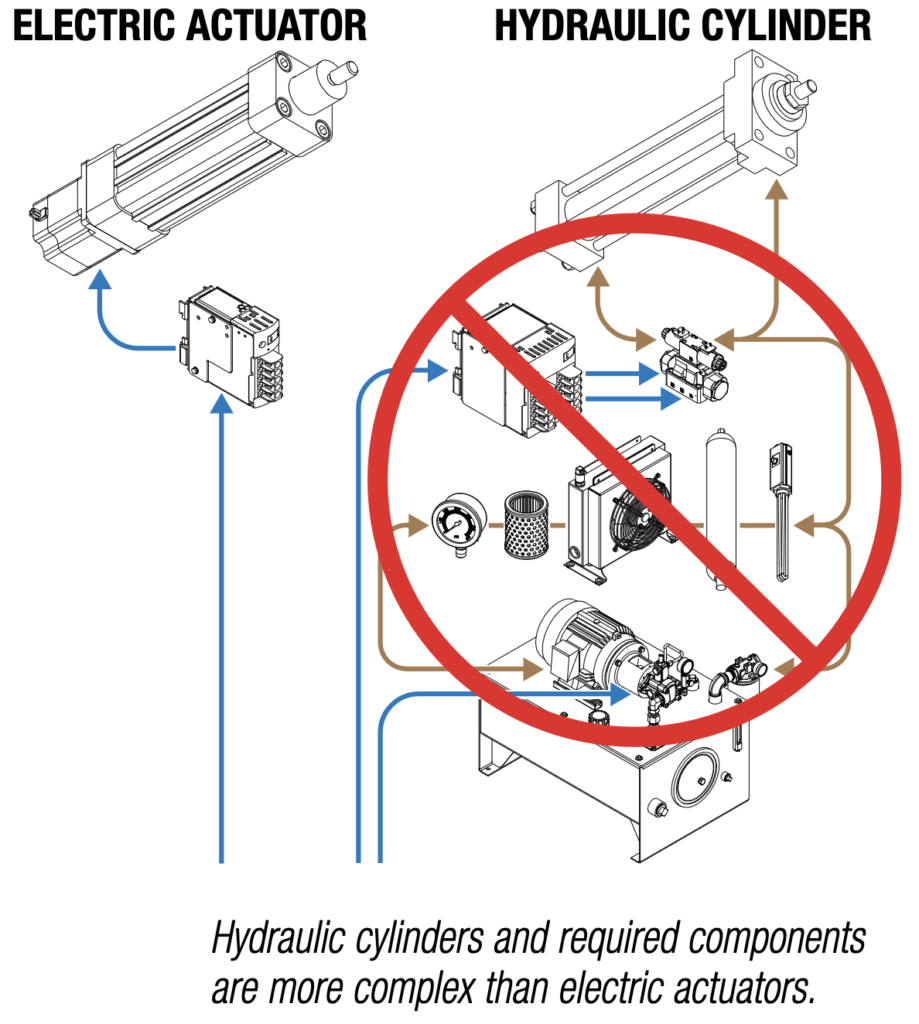

Benefits of Electric Linear Motion Systems over Hydraulic Systems

- Control, Feedback & Data Collection: An actuator’s servo motor/drive system provides precise measurement and control of position, speed, acceleration, and force (torque). This information is available on a continuous basis for tracking and auditing purposes.

- Life and Maintenance: Properly sized and applied electric actuators have a long service life and require minimal maintenance.

- Safety: Light curtain, 2 hand control, guarding configurations available.

- Environmental Concerns: Electric actuators do not contain fluids and therefore do not pose the contamination hazard of hydraulic systems. In addition, temperature fluctuations have less impact on electric actuators.

Designing and Building a Complete Solution

Design and model the correct Tolomatic actuator into your press.

- Sizing and selection: https://sizeit.tolomatic.com

- Design and technical assistance: https://www.tolomatic.com/contact-an-engineer/

- Validation and modeling: https://www.tolomatic.com/info-center/cad-library/

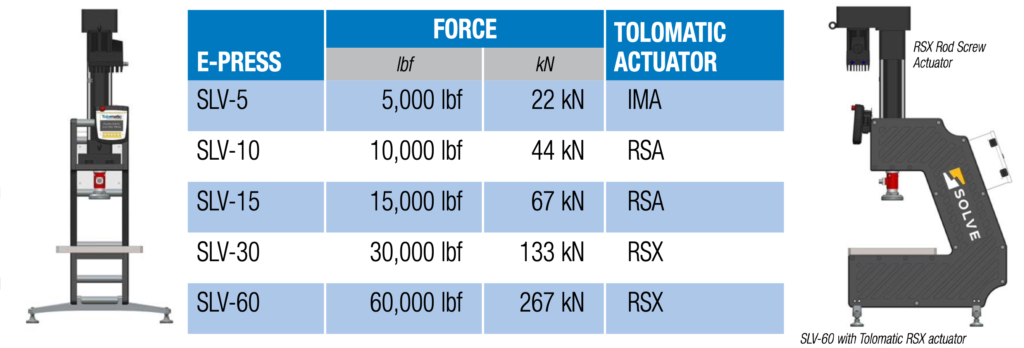

Select an E-Press from proven pre-engineered designs

- Includes electric motor, actuator and fixture

- Pre-engineered designs, stroke configurable

- Specify the motor of your choice with Tolomatic’s Your Motor Here program

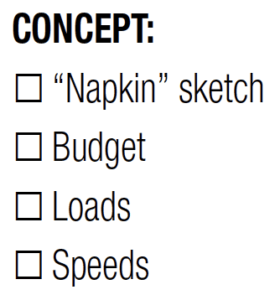

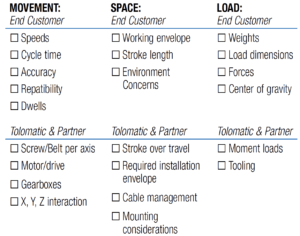

Easy three step process to a custom solution

- Tolomatic can collaborate through our local distributor or work with your systems integrator

- Use this service for new systems or difficult retrofit challenges

Begin with: |

Key Design Considerations |

Quote and Order |

||

Download pre-configured gantry system CAD model

|

Pre-set configurations can be ordered as is or identify any needed modifications: |

Find your Distributor

|

||

|

|

|

Webinar On Demand:

“Tired of hydraulic grime & scrap? There’s a better way”

Electromechanical actuators can provide superior performance over hydraulic cylinders in many applications – through improved precision, flexibility and reliability. This webinar covers:

- Considerations for making a change from hydraulics

- Benefits of electric linear motion systems

- Total cost of ownership

- Important tips for converting from an existing hydraulic system to an all-electric solution

Customer Stories

Bottom line: What do customers have to say about working with us? Check it out…

Tube-bending machines make parts

Tube-bending machines make parts

for objects we take for granted every day.

Tube-Bending Machine

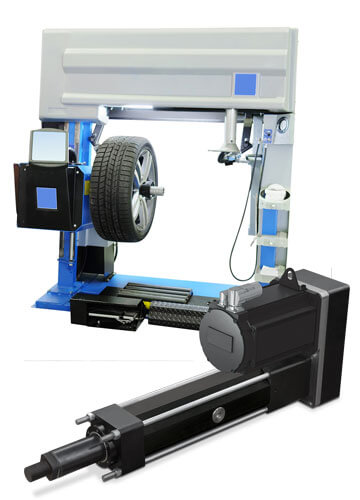

The servo controlled RSX actuator allowed the OEM

The servo controlled RSX actuator allowed the OEM

to create quick and easy changeover procedures

to accommodate any wheel size.

Wheel Bearing Press

Although the hydraulic cylinders could achieve

the forces required for the application,

they could not deliver the force repeatability and accuracy

to achieve a high level of part quality.

Powertrain Assembly

With a precise servo controlled electric actuator system,

the OEM was able to completely eliminate defective parts

from the pressing operation.

Air Bag Production

The hydraulic system was not very efficient

The hydraulic system was not very efficient

and cost thousands each year to operate.

Tire Inspection Press

Electric Pressing Products

RSX Extreme Force Electric Rod Actuators

Roller screw driven

Forces up to 50,000 lbf (222 kN)

Flexible motor mounts

RSA-HT Heavy Duty Electric Rod Actuators

Add any servo motor

Forces up to 13,039 lbf (58 kN)

Economical ball screw options

IMA Integrated Servo Motor Actuators

Integrated servo motor design

Forces up to 6,875 (30.6 kN)

Compatible with many servo drives

Ask an Engineer

Ask an Engineer