Webinar: tips on electric rod actuator selection

When you’re called on to specify electric linear actuators, one of the critical decisions you’ll face is whether to use a rodless or rod-style model. Either actuator type has advantages and disadvantages.

In general, if the actuator has to carry a load, a rodless product is what you need. However, if a load needs to be pushed or pulled, select a rod-style actuator.

Hygienic linear actuator keeps it clean

The world of food production and packaging is broad, varied and ever-changing. That world needs filling machines as diverse as the range of food products they process. Some filling machines have to handle powders and dry solids while others must handle thin or thick liquids. Some machines fill to a specified level, and some fill by volume or weight. This wide variety of equipment has a unifying need, though -- a need for hygienic design that can keep food products uncontaminated and withstand even the most stringent cleaning procedures.

Linear actuators help prevent food contamination

Until recently, the food processing industry has handled contamination reactively. If a foodborne illness was traced back to contamination at a manufacturing plant, the FDA (Food and Drug Administration) had the manufacturer fix the problem.

The flaw in this system, though, was that most of these illnesses were preventable. The Centers for Disease Control and Prevention estimates that 48 million people (1 in 6 Americans) get sick, 128,000 are hospitalized, and 3,000 die each year from foodborne diseases. That makes food contamination a major public health issue.

The federal government stepped in to change the way the FDA and food producers operate with the Food Safety Modernization Act (FSMA) – signed into law in January 2011. This important legislation shifts the focus to preventing contamination problems instead of just responding to them. FSMA affects all automation components used in the industry, including linear actuators.

Calculating total cost of linear actuators [INFOGRAPHIC]

Not too long ago many machine designers only considered the purchase price of automation components, like linear actuators, when they analyzed cost. And manufacturing management only looked at acquisition cost when they considered investing in automation.

Now machine designers and manufacturers are using a more thorough approach to cost analysis. Rather than looking at purchase price alone, they are looking into the “total cost of ownership” of a component, machine or technology. It's a business finance concept, used frequently when considering computer system upgrades.

Electric linear actuator fills accuracy need under harsh conditions

Volumetric filling applications of any type require high levels of accuracy and repeatability. If the filling operation is part of a food and beverage processing plant, there are additional important factors. Factors like food safety and the ability to withstand even caustic washdowns.

Filling equipment designers often rely on electric linear actuators for crucial motion control. Like the machines they’re a part of, these electric actuators need to deliver accuracy and repeatability and may need to stand up to a challenging industrial environment.

Rodless electromechanical linear actuator selection: A webinar

Rodless or rod-style linear actuator? It’s a basic and critical decision point for any machine designer. Consider the specifics of your application. Either actuator type has advantages and disadvantages. In general, if a load needs to be pushed or pulled, select an electric rod actuator. However, if you need an actuator to carry a load, a rodless product is what you need. Want to reduce the complexity of a linear motion system? A rodless electromechanical linear actuator can eliminate the need for load-bearing and guiding elements. Also, a rodless actuator can reduce the footprint of a system since its stroke lies completely within its body.

Electric linear actuator lead screws – article round-up

When it comes to specifying an electric linear actuator, selecting the right lead screw* (sometimes referred to as the leadscrew) for the application is critical. That’s because the screw is the major drive component in most electric actuators. After all, if it’s not a belt-driven actuator, then there’s a lead screw involved.

Electric linear actuator stands up to moisture, dust

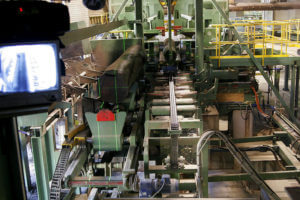

Linear actuators used in sawmills are often subjected to dusty and wet conditions. If the right electric linear actuator isn’t specified, the component may fail and cause expensive downtime. Given the pressure to keep production costs down and output up, it’s essential to match the actuator to the manufacturing environment.

A good way to do this is to refer to a rating system. We use the IP (Ingress or International Protection) system because it evaluates ingress of both dry particles and moisture. An application where there is both dust and water spray needs electric linear actuators rated IP67 for a high degree of protection.

Linear actuator article round-up

Linear actuators are important pieces of industrial automation equipment. Without them parts wouldn’t move into place for the next production step, finished goods wouldn’t get to the right palate, and tools might not reach the spot they need to be in to do their work.

A lot rides on these automation components, so engineers need to know as much about them as they can. At Tolomatic linear motion is our core expertise. We watch what’s written in key trade publications. Here’s a round-up of recent articles that will help you learn more about linear motion.

Integrated linear actuator increases manufacturing efficiency

Production cost and efficiency are important considerations in all manufacturing, but these factors take on critical status in some segments. Small-engine production is one of these. Using the right linear actuator can boost efficiency and reduce cost.