Hydraulic vs high force electric linear actuators: new infographic

By Tolomatic on November 29, 2016

Choosing the best linear actuator for a task takes a thorough understanding of the application. The basics like the weight of the load, the distance the load’s to be moved, and the speed and force needed are all important factors. A machine designer may also need to consider variables like environmental conditions, data collection and reporting, as well as flexibility/programmability requirements.

Choosing the best linear actuator for a task takes a thorough understanding of the application. The basics like the weight of the load, the distance the load’s to be moved, and the speed and force needed are all important factors. A machine designer may also need to consider variables like environmental conditions, data collection and reporting, as well as flexibility/programmability requirements.

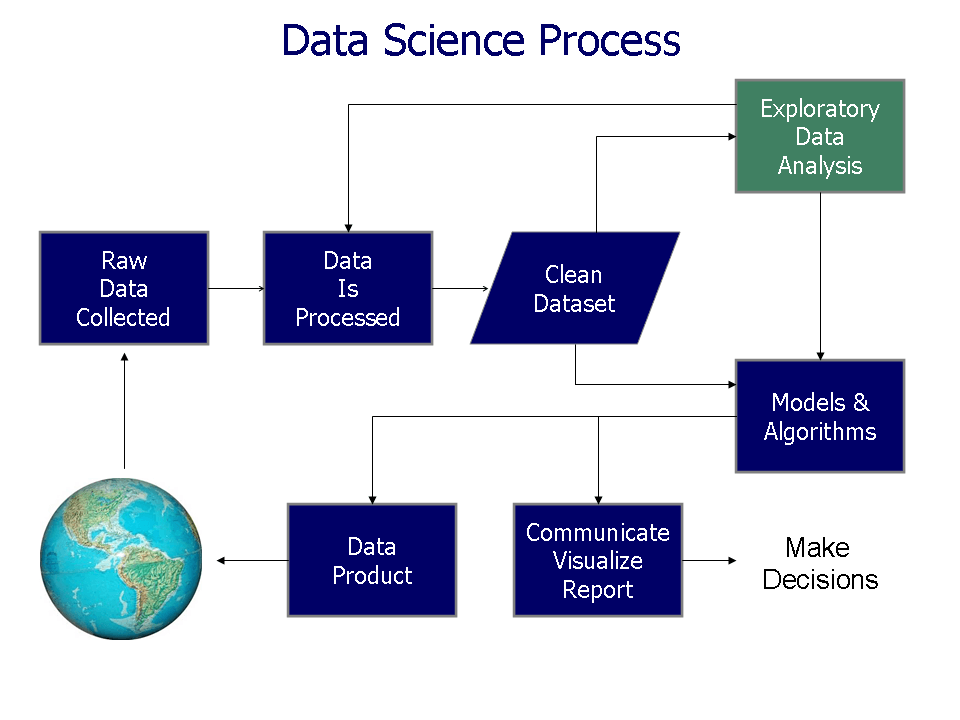

If the application calls for a high force linear actuator, the usual solution has been a hydraulic cylinder. However, high force electric linear actuators are now available (many with roller screws) and offer distinct advantages. Our new infographic (available for download) compares the performance of electric, hydraulic and servohydraulic actuators on intelligence and operational parameters.

For even more information on the strengths and drawbacks of these technologies, see our white paper that compares hydraulic and electric linear actuators.

Intelligence

Control of motion variables

- A hydraulic cylinder works well in simple, end-to-end positioning applications. However, applications that call for mid-stroke positioning require a servohydraulic actuator with a more complicated set-up.

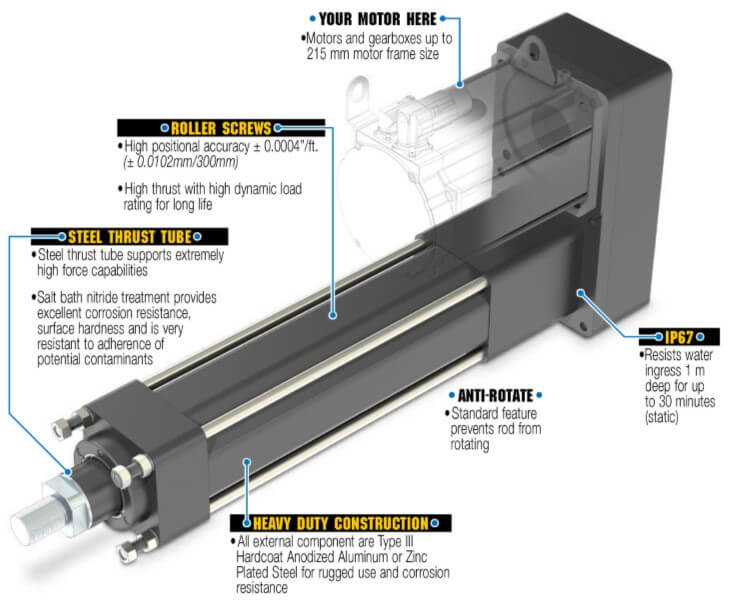

- An electric actuator with roller screw and servo drive/motor (like our new RSX extreme force electric rod actuator) offers infinite control over position, velocity, acceleration/deceleration, output force and more. Adjustments can be made on the fly, plus accuracy and repeatability are far better than that of a hydraulic system.

Data collection and reporting

Data collection and reporting

There’s an emphasis on continuous improvement in manufacturing. Management wants to monitor and measure all aspects of production performance. This calls for data collection at the work point.

- Standard hydraulic actuation systems don’t have data collection capabilities. Only expensive, complex servohydraulic systems with additional sensors can track and monitor position, velocity, force and so on at the work point.

- Sensing capability is built into an electric actuator’s servo system. Motor current monitoring tracks force and repeatability. The motor’s feedback device registers position and velocity.

Operation

Electricity costs

- Hydraulic systems are typically 40-55% efficient in converting electrical power to motion. Also, the HPU needs to be powered up whenever the system is on to keep it pressurized, resulting in inefficient use of power.

- Electric linear actuator systems, like the RSX-096 hydraulic class electric linear actuator, typically operate in the 75-80% efficiency range. When an electric actuator is at rest, it needs little or no current to hold its position.

Sensitivity to temperature

- Hydraulic oil gets thicker and slower-moving in the cold resulting in sluggish and inconsistent actuator performance. In higher temperatures, caused by overheating or the environment, oil degrades and seals fail.

A tank heater can maintain operating temperature in the cold. A heat exchanger can mitigate overheating. However, these additional system components mean additional cost.

- Due to their higher efficiency, electric actuator systems can run at the desired temperature for the given amount of work required. Also, electric actuators can be specified with optional extreme temperature grease for fast response in the cold.

RSX extreme force, hydraulic class electric actuators

Our new RSX extreme force electric linear actuators are more efficient and flexible than hydraulic cylinders. Using roller screw technology, RSX actuators are designed and tested for 100% duty cycle. The first RSX actuator in the family, the RSX-096, delivers up to 30,000 lbf (133.5 kN). It can withstand extreme conditions and cold weather operation.

Our new RSX extreme force electric linear actuators are more efficient and flexible than hydraulic cylinders. Using roller screw technology, RSX actuators are designed and tested for 100% duty cycle. The first RSX actuator in the family, the RSX-096, delivers up to 30,000 lbf (133.5 kN). It can withstand extreme conditions and cold weather operation.

Ask an Engineer

Ask an Engineer