Electric high speed linear actuator reduces conveyor’s TCO

By Tolomatic on October 31, 2017

Higher production speeds usually translate into higher output volumes – a good thing in manufacturing. At least it’s good if product quality stays high and operating costs remain in line. Machine designers are on the look-out for high speed linear actuators and other devices that can streamline processes. But those high-speed solutions need to be reasonably priced and efficient to use.

Higher production speeds usually translate into higher output volumes – a good thing in manufacturing. At least it’s good if product quality stays high and operating costs remain in line. Machine designers are on the look-out for high speed linear actuators and other devices that can streamline processes. But those high-speed solutions need to be reasonably priced and efficient to use.

Designers don’t simply look for the cheapest product. They analyze purchase price and the combination of all operating costs over the life of a competing device to come up with each option’s total cost of ownership (TCO). Our white paper, Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership, compares TCO of two popular linear actuation technologies. Get your copy here.

Pneumatic cylinders can’t keep up

Conveying systems are found throughout manufacturing, moving products and parts from one location to another. Speed is critically important in conveyors since the goal is to maximize throughput.

A conveyor manufacturer was developing a new family of affordable, all-electric (no compressed air needed) conveyors. These new systems would feature an electric lane diverting system for use in expansive installations.

The previous product family had used pneumatic cylinders in the lane diverting system. However, the cylinders’ performance was at the mercy of pressure fluctuations in the compressed air system. The cylinders were slow and unresponsive. Plus, their need for ongoing maintenance and repair made the cylinders costly in the long run.

The new electric design needed to incorporate high speed linear actuators that were more responsive and efficient to operate than the pneumatic cylinders. Also, the OEM wanted to keep their proprietary control system. The electric actuators needed to be compatible.

High speed linear actuators meet the need

We recommended ERD15 rod actuators with servo motors and ACS servo drives for this application since ERD cylinders are affordable, long lasting and optimize the speed and responsiveness of the lane diverting system. We created a pneumatic mode in our ACS drive to mimic the existing pneumatic logic and allow the customer to integrate the electric solution without changing its controls or software.

ERD electric cylinders are fast and responsive, providing quick and accurate moves when needed. With ERD’s minimal maintenance needs, long service life, better operating efficiency and lower energy consumption, the new electric lane diverting system offers lower TCO than the previous system.

ERD electric cylinders and ACS

ERD electric cylinders and ACS

ERD low-cost electric cylinders are the perfect alternative to pneumatic cylinders for automating manual processes. The ERD is an economical electric cylinder and is compatible with many NEMA and metric mount stepper and servo motors. When combined with a motor and ACS drive, ERD cylinders create a flexible, powerful, cost-effective electric actuator solution that can out-perform traditional pneumatic cylinders.

Download our ERD series catalog here.

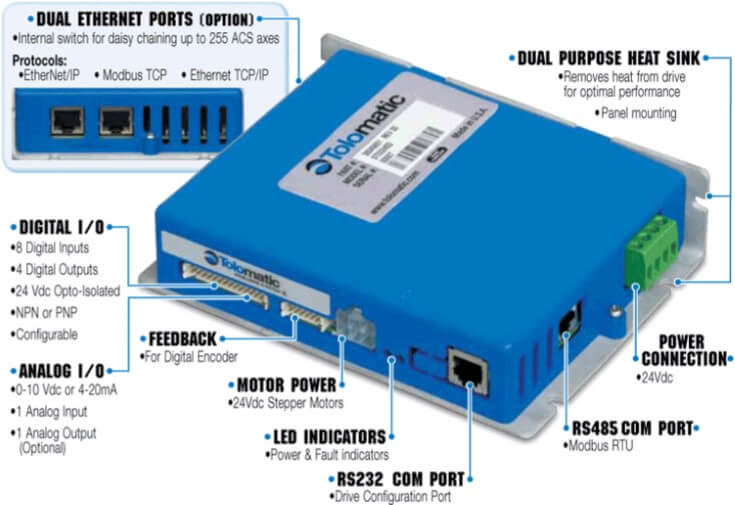

ERD cylinders are often combined with our ACS driver/controller, available for servo motors and stepper motors, to create a low-cost, easy-to -use actuator and motor control system. The ACS was developed specifically for electric actuators and can be configured with ease using the installed driver software. The pneumatic mode replaces pneumatic valve operation for simple motion.

-use actuator and motor control system. The ACS was developed specifically for electric actuators and can be configured with ease using the installed driver software. The pneumatic mode replaces pneumatic valve operation for simple motion.

Learn more

For a thorough review of pneumatic and electric actuation and the total cost of ownership of these technologies, download our white paper, Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer