Electric high-force linear actuators improve powertrain assembly process and part quality

By Tolomatic on May 14, 2019

In automotive and heavy equipment industries machine designers and engineers know part quality and reliability are critical. That is why they often evaluate multiple linear motion technologies (hydraulics, pneumatic, electric) to determine the optimal solution for their component assembly or joining processes. It is imperative for their machines to produce quality parts that stand up to even the most demanding environments in harsh powertrain applications. Luckily, electric linear actuators offer engineers a solution for improving machine flexibility, precision, and reliability where legacy fluid power technologies (pneumatic and hydraulics) often fall short.

In automotive and heavy equipment industries machine designers and engineers know part quality and reliability are critical. That is why they often evaluate multiple linear motion technologies (hydraulics, pneumatic, electric) to determine the optimal solution for their component assembly or joining processes. It is imperative for their machines to produce quality parts that stand up to even the most demanding environments in harsh powertrain applications. Luckily, electric linear actuators offer engineers a solution for improving machine flexibility, precision, and reliability where legacy fluid power technologies (pneumatic and hydraulics) often fall short.

For an overview of how electric high-force linear actuators compare to hydraulic cylinders, see our white paper, Electric rod actuators versus hydraulic cylinders: a comparison of the pros and cons of each technology.

The following case study describes a real-world example from the agricultural industry. A premier heavy equipment OEM evaluated multiple technologies and their decision resulted in a successful conversion from hydraulics to electric for a new power train parts assembly line. This type of conversion is common because electric linear actuation offers compelling benefits over hydraulic systems.

Powertrain parts assembly needs precise reliable linear motion

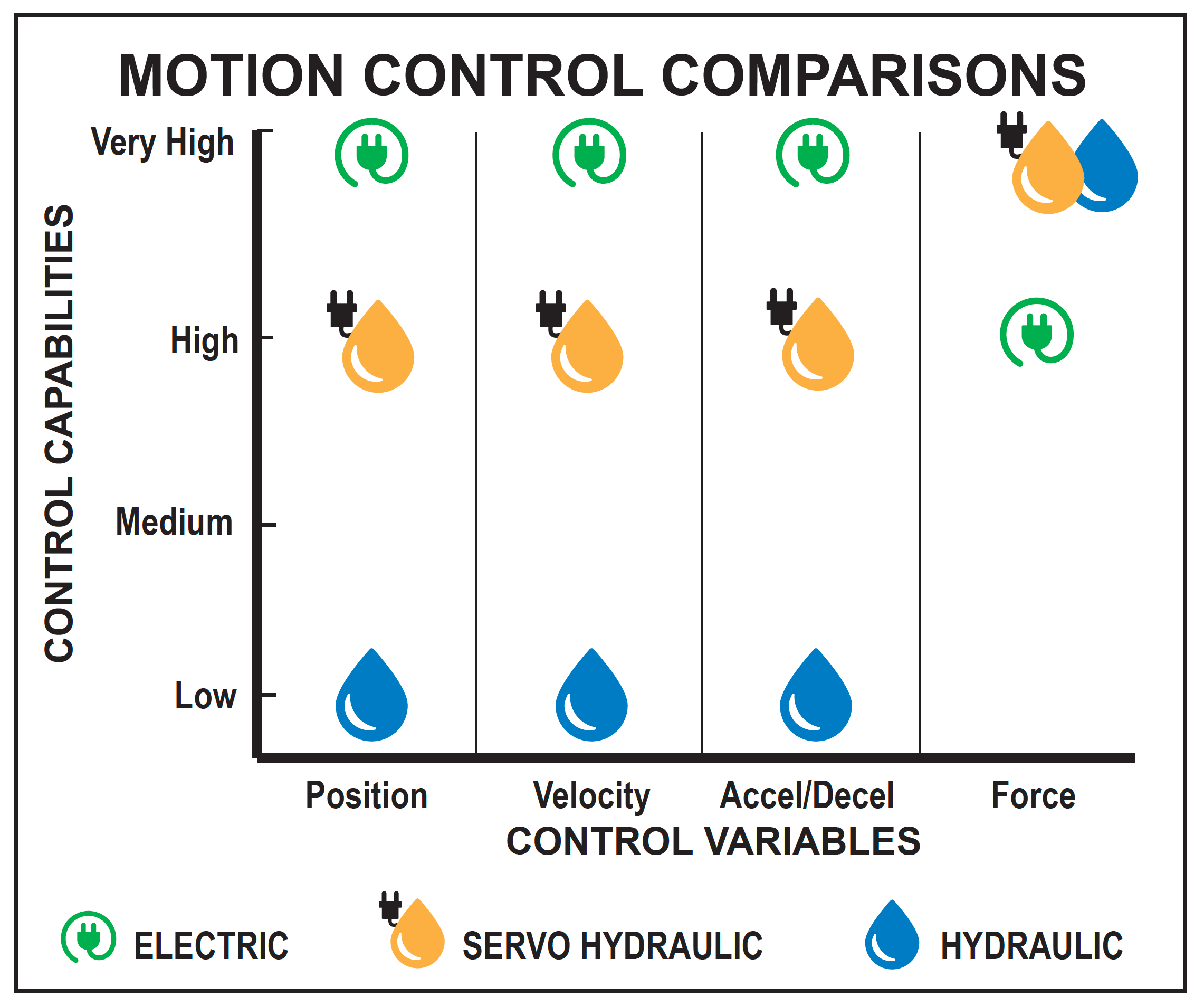

The benefits of electric linear actuators were extremely important to this OEM who was building a new assembly line. They wanted to improve part quality, assembly cell changeover times, and line reliability. Previous assembly stations utilized hydraulic cylinders and struggled with controlling the motion profile throughout the assembly process. As a result, they were challenged with inconsistent part quality. The OEM evaluated electric actuator solutions and discovered this technology provided improved control over the motion profile along with increased accuracy and repeatability. These factors resulted in significant improvements to the quality of parts produced with the electric actuator systems. The graphic shown below compares the capabilities of electric, servo hydraulic, and hydraulic motion control. Control over all aspects of motion can be extremely important in critical applications where precision position, speed and force come into play.

The benefits of electric linear actuators were extremely important to this OEM who was building a new assembly line. They wanted to improve part quality, assembly cell changeover times, and line reliability. Previous assembly stations utilized hydraulic cylinders and struggled with controlling the motion profile throughout the assembly process. As a result, they were challenged with inconsistent part quality. The OEM evaluated electric actuator solutions and discovered this technology provided improved control over the motion profile along with increased accuracy and repeatability. These factors resulted in significant improvements to the quality of parts produced with the electric actuator systems. The graphic shown below compares the capabilities of electric, servo hydraulic, and hydraulic motion control. Control over all aspects of motion can be extremely important in critical applications where precision position, speed and force come into play.

Electric high-force linear actuators provide OEM clean reliable motion solution

Electric roller screw actuators were chosen because of their precise positional accuracy, repeatability, and long, reliable life. Additionally the electric actuators provided flexibility for quick product changeovers and were a clean technology option that eliminated leaks and unplanned downtime often experienced with hydraulic systems. Tolomatic’s RSA and RSX electric high-force linear actuators were selected. The numerous assembly stations and operations for the powertrain components all required different force and speed requirements. Tolomatic’s diverse product portfolio offered a variety of actuator sizes, screw technologies such as planetary roller screws, and screw lead choices, allowing selection of the right sized actuator and screw for each application. Tolomatic’s Your Motor Here® Program provided a convenient mounting option for the OEM’s servo motor of choice — and facilitated seamless integration into their controls system — streamlining time required for line commissioning.

RSA and RSX high-force linear actuators

The RSA Series electric linear actuator is an industrial grade actuator platform available in both ball screw and roller screw configurations to provide forces up to 58 kN (13,039 lbf). The RSX Series high-force linear actuator, with planetary roller screw, is designed for forces up to 180 kN (40,000 lbf).

Resources

Learn more about the advantages of converting hydraulics to electric actuator systems, and for tips on how to measure a hydraulic system for force to size an electric actuator system.

Ask an Engineer

Ask an Engineer