Electric high-force linear actuator choices. Ball vs roller screw

By Tolomatic on October 16, 2018

Many applications require high-force linear actuators – like moving equipment in a foundry or powering a press in metal forming or guiding heavy logs in a sawmill. Whatever the application, a machine designer is faced with a choice…whether to specify a ball or roller screw in the electric high-force linear actuator.

Many applications require high-force linear actuators – like moving equipment in a foundry or powering a press in metal forming or guiding heavy logs in a sawmill. Whatever the application, a machine designer is faced with a choice…whether to specify a ball or roller screw in the electric high-force linear actuator.

There are multiple factors to consider in this choice, like:

- Duty cycle Ratio of the actuator’s working time to total cycle time.

- Expected service life Number of cycles the actuator is expected to last.

- Footprint of the actuator Space your design allows for the actuator.

- Budget Total cost of ownership budgeted for the actuator.

You can find a discussion of the pros and cons of roller and ball screws on our website. And we offer a complete guide to all actuator power screws in our publication, Which Screw? Download your copy here.

Screw technologies

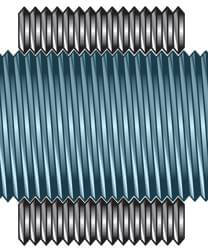

- Roller screws have triangular-shaped, precision-ground threads that match multiple precision-ground threaded rollers in the nut. Screw

components are designed with a fine pitch, providing many points of contact and a large contact radius. The result is less stress per point of contact.

components are designed with a fine pitch, providing many points of contact and a large contact radius. The result is less stress per point of contact.

These screws have very high force transmission capabilities since the rollers have significant contact with the screw threads. They can deliver high force, operate at high speeds, are long-lasting and require little maintenance.

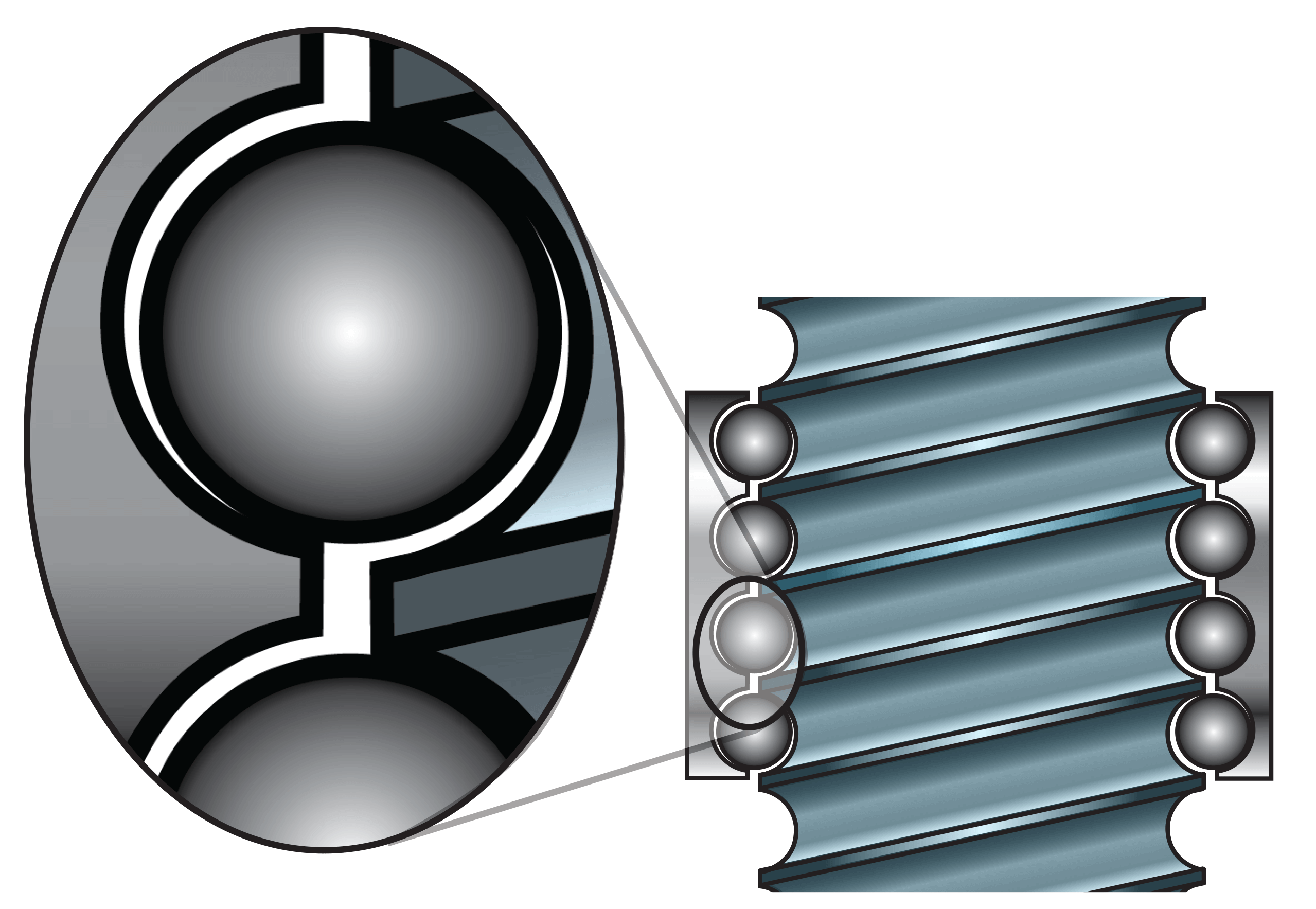

- Ball screws are named for the re-circulating ball bearings that fit between arch-shaped screw threads and corresponding threads in the nut. The ball bearings transmit force and relative motion efficiently as they roll through one or more circuits in the nut.

These screws have fewer points of contact and are less effective in transmitting force. While ball screw actuators can be back-driven and are often noisy, their lower cost and reliability make them ideal for applications that require moderately high thrust and speeds.

These screws have fewer points of contact and are less effective in transmitting force. While ball screw actuators can be back-driven and are often noisy, their lower cost and reliability make them ideal for applications that require moderately high thrust and speeds.

A comparison of screw types

In terms of the factors listed above, here’s how these screw types compare:

- Duty cycle Roller screws operate well in high duty cycle applications. Ball screws are better suited to lower duty cycle uses.

- Expected service life A roller screw’s higher Dynamic Load Rating (DLR) means it will last much longer than a ball screw.

|

SPECIFICATION |

ROLLER |

BALL |

|

Dynamic Load Rating |

Very High |

Medium |

|

Screw Life |

Very Long |

Moderate |

|

Space Required |

Minimal |

Moderate |

(DLR is an industry term that represents the highest load a power screw can handle and achieve 1 million revolutions of rated life at 90% reliability. DLR is usually provided by the actuator manufacturer.)

- Footprint of the actuator Because roller screws pack more force into a smaller package, the actuators they power are more compact.

- Budget It takes some analysis to determine which screw type is more affordable for an application. Ball screw actuators are usually less costly initially, so in the right application they can have a lower total cost of ownership. However, if the application’s requirements will break down a ball screw actuator prematurely, a roller screw actuator that can stand up to the demands may be the lowest cost solution in the long run.

We have a staff of experts in electric linear motion ready to help you choose the screw type that fits your application exactly. Contact us.

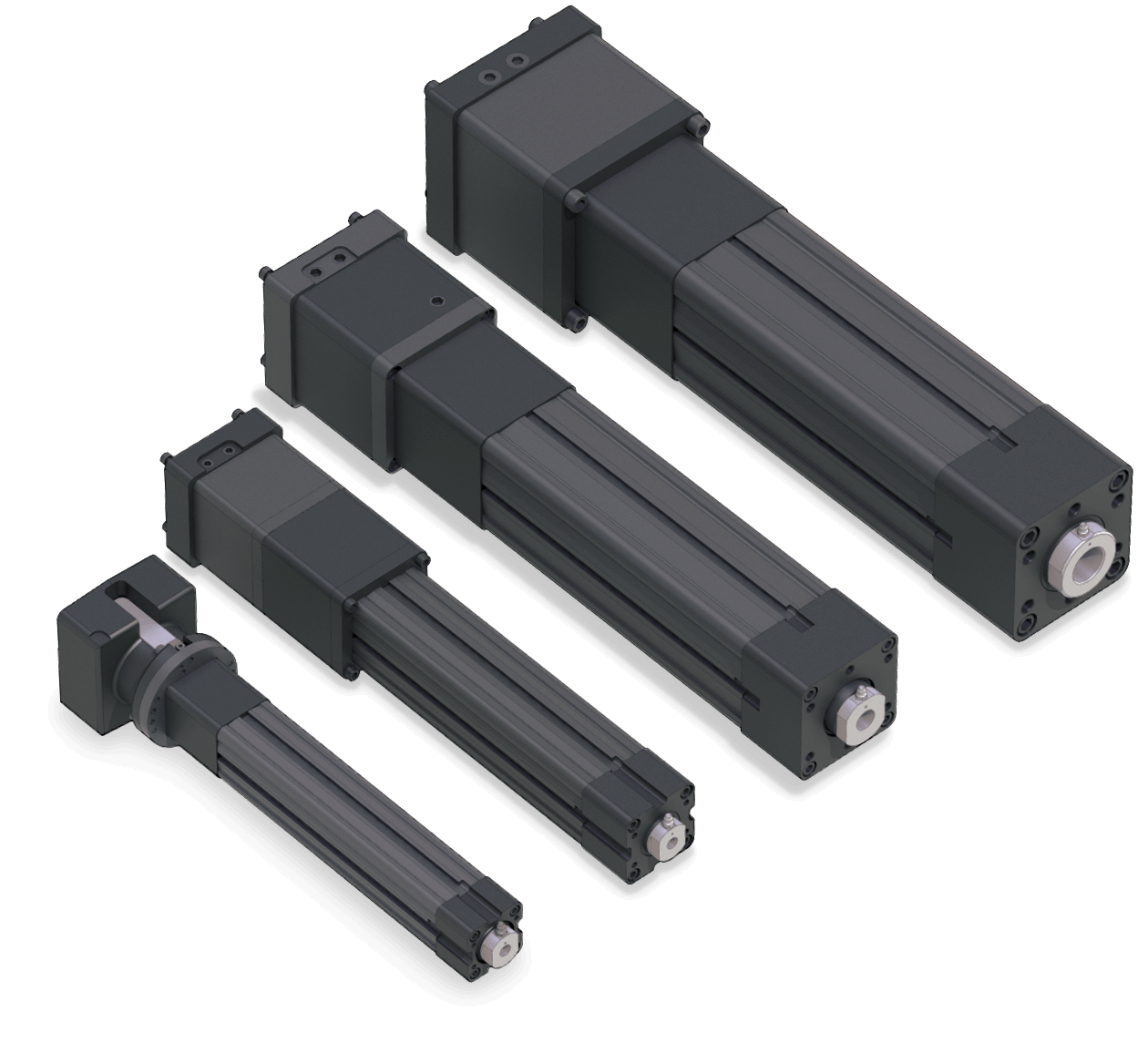

Our high-force products

We offer a range of electric high-force electric linear actuators, many with the option of either screw type.

|

|

ServoWeld Resistance Spot Welding Actuators

|

|

|

RSA-HT heavy duty electric rod actuators

|

|

|

RSX extreme force electric rod actuator

|

|

|

IMA integrated servo motor actuator

|

|

|

IMA food grade linear actuator

|

|

|

ERD hygienic electric actuator

|

Watch our video on industrial linear actuators.

Resources

You can find a discussion of the pros and cons of high-force screw types on our website. And we offer a complete guide to electric linear actuator power screws in our publication, Which Screw? Download your copy here.

Interested in linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer