Choose an Actuator That Actually Matches Your Optimized Design

By John Fenske on October 25, 2024

In the past, engineers tailored machine designs around standard linear actuators with the hope that it would keep costs down and shorten their time to market. But this strategy wasn’t always fruitful. It often compromised the performance of the resulting machine, while the expected cost and time savings were more myth than reality.

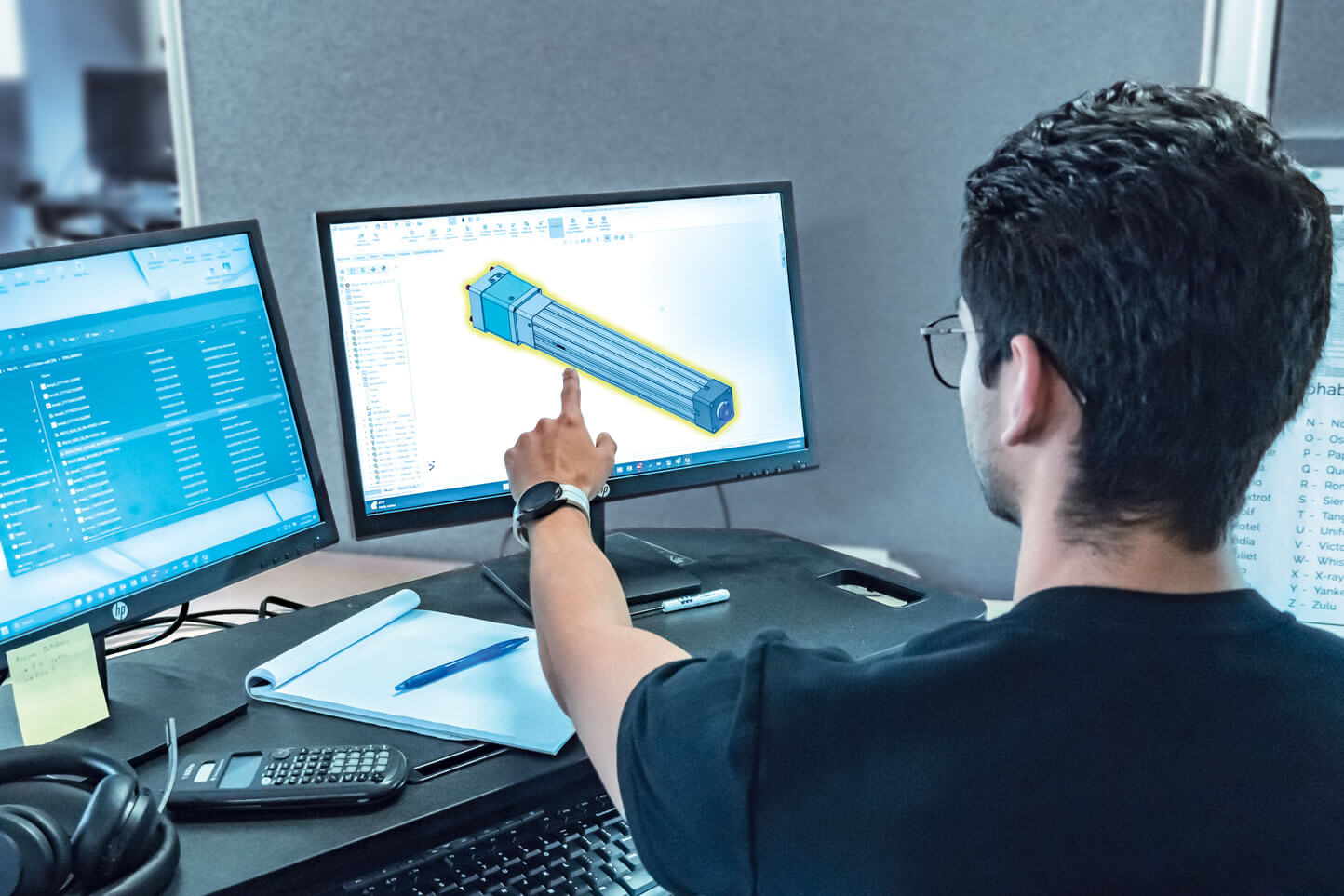

Today, many machine builders are optimizing their machine design first and then selecting an actuator based on that design. Unfortunately, however, many off-the-shelf actuators don’t meet their design requirements in an optimal way, causing the engineer to have to work with an actuator supplier to specify a custom solution.

But don’t assume a custom actuator guarantees longer time and higher expenses; you can avoid the delays and cost if you hold an experienced actuator supplier accountable.

Collaborating with a supplier who specializes in engineered-to-order solutions allows you to optimize your machine design and receive a custom actuator while meeting tight budgets and deadlines. At Tolomatic, we streamline the design process to ensure on-time delivery. When specifying an engineered-to-order solution, our guidelines will help you find an actuator that exactly fits your design. Here are some tips to get started.

Discuss Timeline Expectations

Discussing your timeline should be one of the first conversations you have with your actuator supplier. Meeting strict deadlines is a very common reason why a machine designer would choose an off-the-shelf actuator before a customized one. Whether you need a single one-off design, rapid prototyping or a high-volume production — lead times are critical.

Tight deadlines make it imperative to work with an actuator supplier that is fast, responsive and flexible. We recommend determining if your supplier can meet your timeline as early as possible. Provide the supplier with a forecast of your production schedule and see how they respond. You can also ascertain if the supplier is in control of any key manufacturing processes that will enable them to deliver your actuators faster.

Define the Application

Once you’ve settled on a supplier, define the application and select an actuator that meets your performance requirements — that is, find one that will actually do the work you need. To help gather this information in a structured manner, we provide application worksheets available as online forms or PDFs.

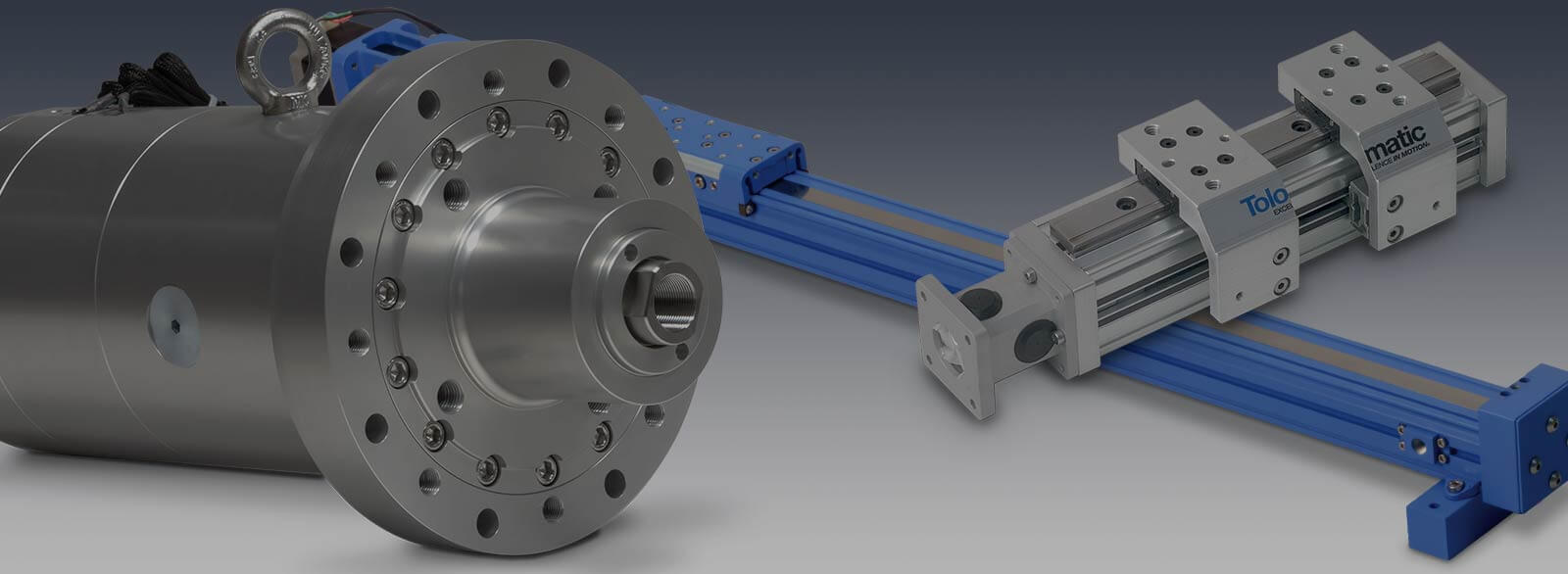

Consider the actuator’s duty cycle: stroke length, cycles, motion profile and forces. These are important considerations because they influence which drive mechanism best fits your application. In both rod and rodless actuators, the drive mechanism determines duty cycle, performance and lifespan. Find out which drive mechanisms are available with your supplier.

Consider the Environment

Be aware of the environmental conditions in which your machine will operate. Consider temperature extremes and how they can affect actuator performance. It’s important to protect the drive system from dust, dirt, debris and other particulates. Exposure to moisture, liquids and chemicals are also a concern if they make contact with internal driving components.

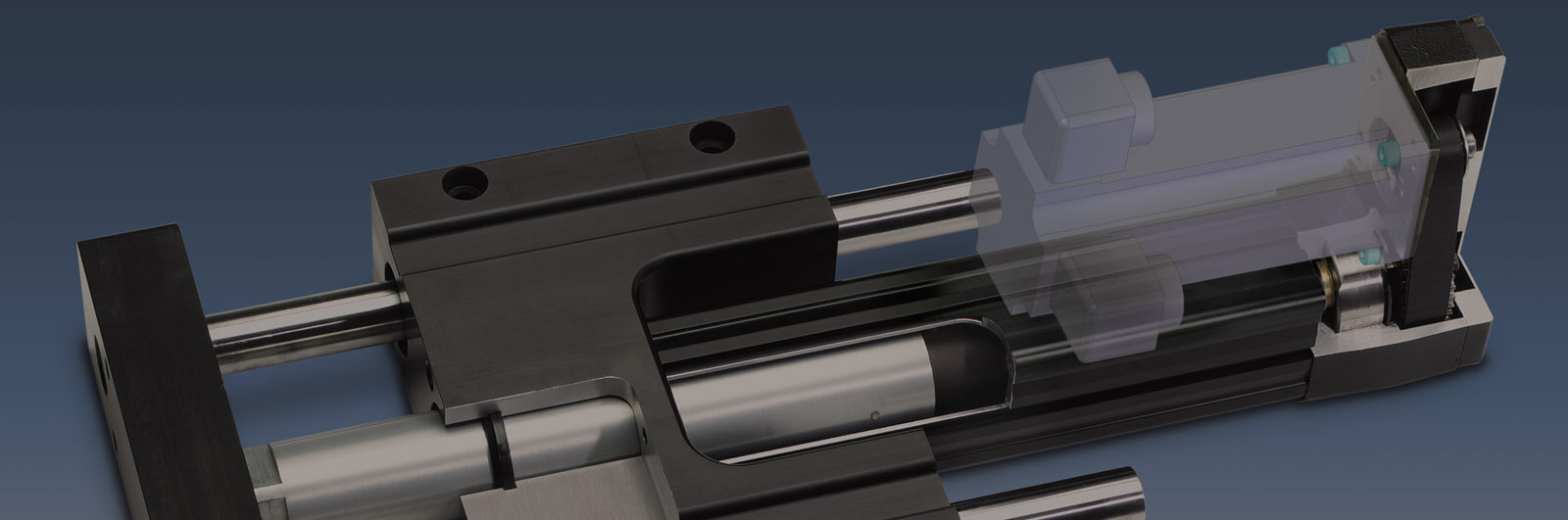

For rod style actuators, proper seal selection is crucial to protecting the drive mechanism. When selecting seals, consider their chemical and wear resistance, as well as operating temperatures. Maintenance and viability for field replacement are also important considerations for seal specification. Another method of ingress protection is to include breather ports into the actuator design that prevent incoming contamination by generating positive pressure. Protecting a rodless actuator may lead you to a design with a fully enclosed drive mechanism.

Understanding your environment will guide you in selecting the construction materials, surface finishes and gland geometry. For example, you may want your actuator to be entirely painted with white epoxy. Or, if you’re designing for a food application, you may require an actuator with IP69K-rated protection.

Optimizing for Size

Once you’ve gathered your preliminary application data, plug it into sizing software like SizeIt, which is available on our homepage and provides a list of actuators that meet your performance requirements. From this list, choose an actuator that physically fits into your optimized machine design. You’ll need access to CAD models and drawings to verify the physical fit — like those available in our CAD library.

To optimize space and weight utilization in your machine, consider actuators with variable stroke lengths. Some actuators have incremental stroke lengths that can lead to excess length, or dead length. Unnecessary length contributes to excess space and weight. You can avoid dead length by determining the exact stroke length your application requires.

Mounting configurations play a large role in optimizing an actuator’s physical fit and contribute to how the actuator interacts with the forces of the machine. In rod style actuators, connection options will also influence how the actuator interacts with forces. Rodless designs will instead focus on the carrier. Check with your supplier to see the different mounting, connection and carrier options available — and be especially mindful of metric or imperial dimensions.

Another space consideration involves whether or not to specify an integrated or non-integrated actuator. In general, integrated designs are more compact and feature a simpler shape with less dead length than non-integrated actuators.

Account for Control Architecture

Some machine builders count on the control architecture to drive the value of their product, so it’s important to engineer the actuator to seamlessly integrate with it. If using a non-integrated actuator, you’ll need to select the best-fit motor option that facilitates easy integration. With an integrated actuator, you’ll need easy integration with the motor’s drive and all the necessary feedback control mechanisms.

Make sure your supplier is experienced with control architecture integration. At Tolomatic, we’ve integrated hundreds of different motor models for more than twelve different manufacturers.

Your Motor Here

The motor greatly influences the performance of non-integrated actuators, so choosing the proper motor is very important. We offer the Your Motor Here® (YMH) program that enables you to create a mounting plate specific to your actuator-motor combination. Using YMH ensures your actuator arrives ready for motor mounting and includes thousands of motor models across hundreds of manufacturers.

Work With Your Supplier

Actuator designs have come a long way and are more flexible than ever. Instead of shoehorning a standard actuator into a suboptimal design, take advantage of this flexibility. Work with your actuator supplier and rely on their expertise to innovate and meet your machine design requirements in an optimal way. And remember that an engineered-to-order actuator doesn’t mean long lead times and high cost when you hold your supplier accountable.

Contact us to get started.