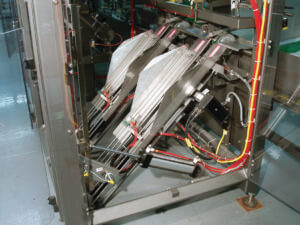

In the bag

Rodless electro-mechanical actuators on a modular bagging system precisely position incoming bags regardless of size.

Pneumatic rodless cylinders: Point-to-point motion control

Rodless cylinder technology has evolved from the first band cylinder, introduced in 1955, to today's high-performance rodless electric actuators.

Motion control keeps material handling systems moving

In these stay-at-home days, online shoppers increase the need for accurate, fast and efficient material handling systems, from processing paper products to packaging, conveying and shipping. Electric actuation is bringing many benefits to applications that have typically been pneumatic.

Electric high speed linear actuator reduces conveyor’s TCO

Higher production speeds usually translate into higher output volumes – a good thing in manufacturing. At least it’s good if product quality stays high and operating costs remain in line. Machine designers are on the look-out for high speed linear actuators and other devices that can streamline processes. But those high-speed solutions need to be reasonably priced and efficient to use.

Electric cylinders essential to advanced conveyor system [Case Study]

Conveying systems are common in manufacturing. They can be straight-forward systems that take packages from point A to point B or complex ones for sorting and diverting. Systems used in food processing also must handle washdowns, a common practice in the industry.

As critical components, linear actuators must withstand the challenges of the application including environmental ones. Pneumatic cylinders have been used extensively in conveying. However, electric cylinder use is growing, fueled by demand for programmability and better accuracy.

Electric linear actuator speeds up changeovers, lowers TCO

Time is money, as the saying goes, and it’s especially true in manufacturing. Reduce the time a process takes and you save operating costs. The concept of total cost of ownership (TCO) considers issues beyond a component’s purchase price like the downtime and labor costs associated with changing production set-ups.

Linear actuator helps convert conveyor to electric

Every factory relies on some kind of conveyor system to take components, work pieces, or finished goods from one place to another. In fact, most factories have several conveying systems, each tailored to a specific need. Conveying equipment is varied and essential. Components in these systems, like linear actuators, must be able to meet these varied needs and provide reliable performance.

Electric cylinders lower cost of conveying equipment

Conveying equipment manufacturers know that fast and efficient systems are critical to manufacturing success. Conveying system buyers are demanding better positioning accuracy, energy efficiency, and lower cost of ownership to ensure their ongoing success. Plus, some are eliminating compressed air systems and asking for electric linear actuators, including electric cylinders, instead of pneumatic solutions. Since they often produce several product models in the same plant, buyers need actuators that are easily programmable to several positioning set-ups.

Ask an Engineer

Ask an Engineer