Ball and roller screw linear actuators: How to compare service life

By Tolomatic on January 10, 2017

When you’re designing equipment, you’ll probably be asked, “How long will this machine last?” And even if you’re not asked outright, you know service life is an essential consideration. It’s a critical factor you consider when sourcing components.

When you’re designing equipment, you’ll probably be asked, “How long will this machine last?” And even if you’re not asked outright, you know service life is an essential consideration. It’s a critical factor you consider when sourcing components.

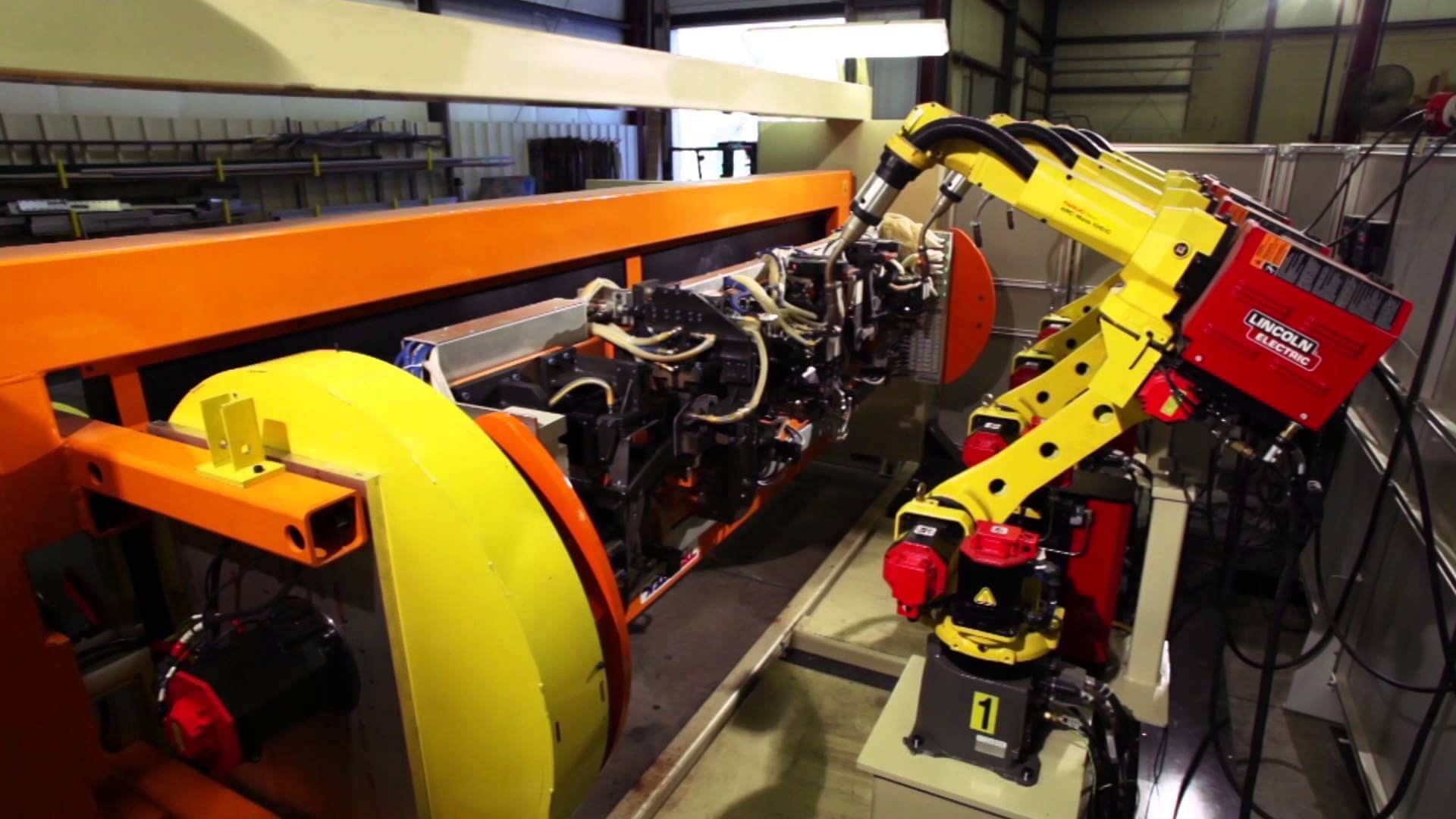

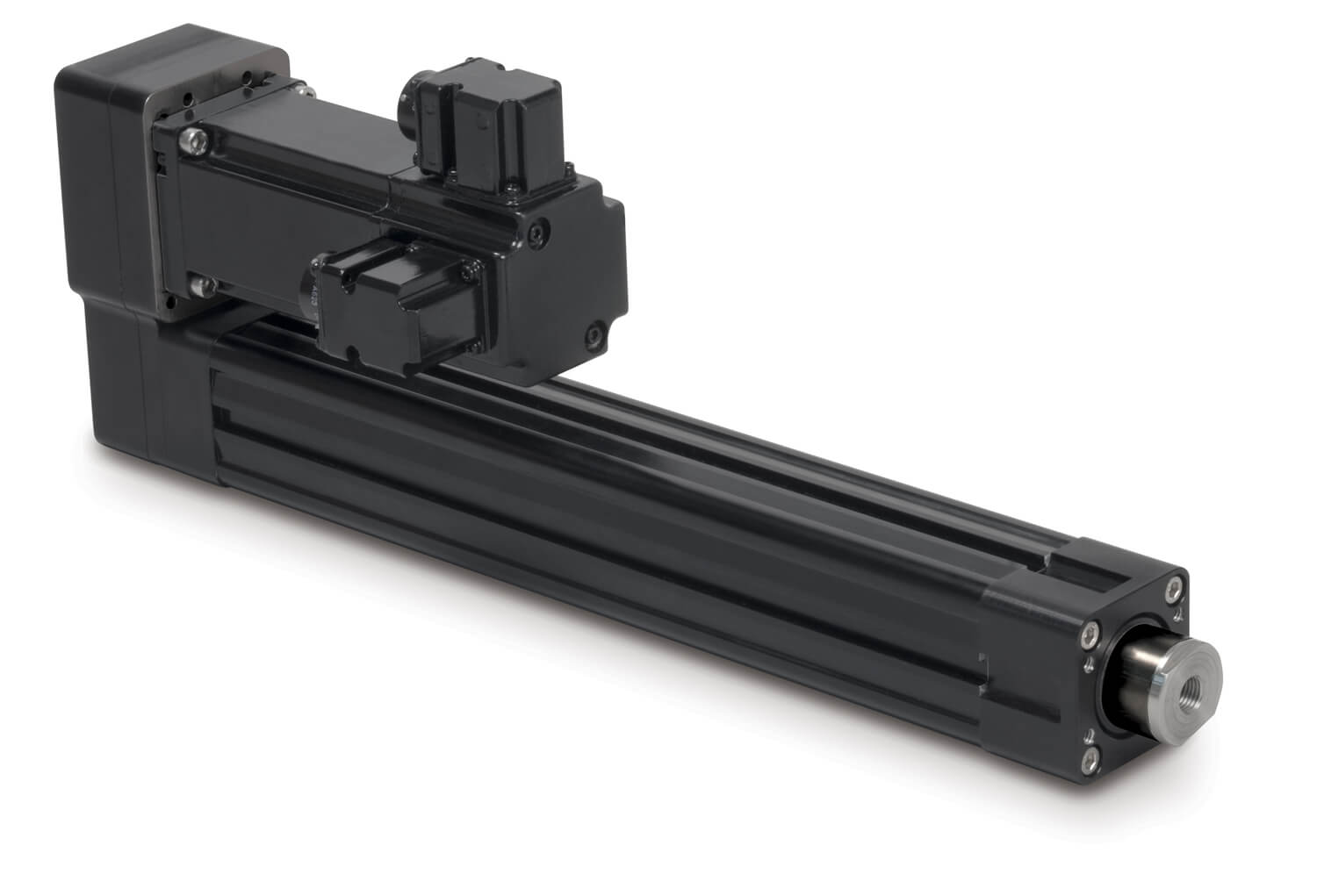

Electric linear actuators are important components in many machines, and the “how long will it last” question is a familiar one. If it’s a ball or roller screw actuator, you can use a formula to help estimate life based on load – the same formula used to estimate bearing life.

This Guide from Tolomatic explains how to use this formula to calculate L10 life for electric linear actuators. The Guide shows you how to estimate life in units of travel and units of time. It even explains how to compare the estimated life of two different actuators. Here’s a summary, starting with a review of terms.

Important terms

Dynamic Load Rating (DLR) is the constant load under which a ball bearing device will achieve 1 million revolutions (rotations). The manufacturer usually provides this information. It’s represented by the letter C.

L10 (or B10) Life is the number of revolutions which 90% of a group of identical actuators have the statistical probability to achieve (or at which 10% can be expected to fail). The calculation assumes a group of identical screw actuators operating under the same conditions.

Comparing actuators

Let’s say you’re considering two actuators for an application. It’s important that you compare the estimated service life (L10 life) of each alternative so you can identify which one will fit your application’s needs best.

Let’s say you’re considering two actuators for an application. It’s important that you compare the estimated service life (L10 life) of each alternative so you can identify which one will fit your application’s needs best.

Use this formula when you’re faced with this situation:

Life comparison of products A vs. B =

(DLR A / DLR B)3 • (Screw Lead A / Screw Lead B)

Use the higher Dynamic Load Rating (DLR) as DLR A.

This formula can be used to compare ball vs. roller screw actuators, two different sizes of the same model, two different actuators from the same manufacturer, or actuators from two different manufacturers.

Examples

When the actuators have the same screw leads –

DLR A (8000 lbf); DLR B (4000 lbf); both with 5 mm lead

A vs B = (8,000/4,000)3 • (5/5) = 8 • 1 = 8

This means product A has an estimated 8 times the L10 life of product B.

When two actuators have different screw leads –

DLR A (8000 lbf) with 5 mm lead; DLR B (4000 lbf) with 10 mm lead

A vs B = (8,000/4,000)3 • (5/10) = 8 • 0.5 = 4

This means product A has an estimated 4 times the life of product B.

Why do we care about screw leads? Because DLRs are based on 1 million screw revolutions, life must be normalized for different leads.

Use with caution

There are two things to keep in mind when using this life calculation:

- The first is that the L10 formula and this comparison formula give you theoretical estimates of service life only. These are not guarantees.

- The second is that load is just one factor affecting actuator life. Other things that can negatively affect life or cause premature failure include incorrect mounting/alignment, lubrication starvation, temperature, and other environmental factors, like corrosive agents.

Learn more

For further explanation of the L10 life calculation, our guide, Actuator Life: How to estimate for ball and roller screw actuators, can be downloaded here.

Ask an Engineer

Ask an Engineer