10 tips for specifying electric rod actuators: Part 1

By Tolomatic on September 12, 2017

There are lots of good reasons for specifying an electric rod actuator. Electric linear actuators offer a high degree of control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often a superior actuation choice compared to pneumatic or hydraulic cylinders.

There are lots of good reasons for specifying an electric rod actuator. Electric linear actuators offer a high degree of control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often a superior actuation choice compared to pneumatic or hydraulic cylinders.

Specifying an electric linear actuator is easier when you use our selection tips. For a more thorough look at them, download our whitepaper. For a quick visual reminder, print our infographic.

Specifying electric rod actuators

Here are the first five of our ten tips.

Tip #1 Know the load

An electric linear actuator’s bearings, motor and power screw are affected by the load being moved. To specify the best electric actuation system, you will need to calculate the load precisely.

Tip #2 Forget fluid-power specifying rules

With fluid power cylinders, the cost of a larger actuator is minor compared to the extra engineering time needed to size it correctly. Engineers may build in a 2:1 safety factor on fluid power applications to compensate for imprecise knowledge of the loads or fluctuations in available air or oil pressure.

Electric actuators usually come with higher initial prices than their fluid-powered counterparts so oversizing can be expensive. Plus, because electric  actuators are not affected by pressure fluctuations and other factors, no built-in safety factor is needed. Calculate actuator size for electric, not fluid power, using the manufacturer’s sizing software to match the actuator to the application.

actuators are not affected by pressure fluctuations and other factors, no built-in safety factor is needed. Calculate actuator size for electric, not fluid power, using the manufacturer’s sizing software to match the actuator to the application.

Tip #3 Consider duty cycle

Duty cycle is a ratio an actuator’s operating time to its resting time. Duty cycle is expressed as a percentage. For example, an actuator that moves for two seconds and stops for two seconds has a duty cycle of 50 percent.

Underestimating duty cycle can cause overheating, faster wear, and premature component failure. Overestimating can lead to oversizing, resulting in higher initial costs.

Tip #4 Understand your application’s force and velocity requirements

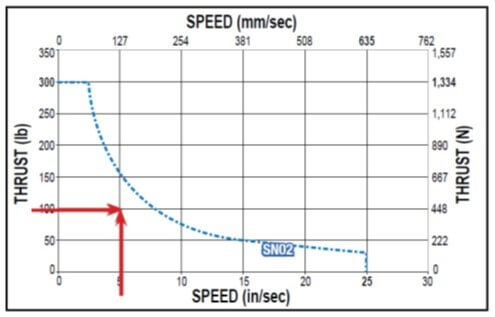

Much like load, force and velocity are critical parameters when it comes to selecting motors, bearings, and power screw/nut systems. Consult with the actuator manufacturer to match the actuator to your application.

Tip #5 Avoid side-loading

An actuator can wear if the extended rod is subjected to even moderate side loads. This usually occurs when the actuator is out of alignment with the main load and can cause wear to the front bearing and damage to the lead nut. You can avoid side-loading by guiding the actuator rod or ensuring that the actuator is accurately aligned with the load.

There are five more tips:

Tip #6 Obey critical speed limits

Tip #7 Match the actuator’s peak thrust to the application

Tip #8 Consider the environment

Tip #9 Make room for the entire system package

Tip #10 Remember: motor mounting affects both system performance and size

See our next blogpost for a full explanation.

Learn more

Our white paper on tips for specifying electric rod actuators will give you the information you need to find the right linear actuator for your application. Download it here.

Interested in electric linear motion? Join the discussion at our LinkedIn group.

Ask an Engineer

Ask an Engineer