Plastics & Rubber Electric Linear Actuators

Electric Linear Actuators for Plastic & Rubber Product Manufacturing

Optimize Productivity and Quality

While Improving the Bottom Line

Plastic Injection Molding

Plastic Vacuum Thermoforming

Product Feeder – Rubber

Electric Linear Actuators

for Plastic Product Manufacturing

With clean, consistent motion control, Tolomatic’s electric linear actuators help optimize productivity, tool life and part quality in plastic product manufacturing. Going electric eliminates costly hydraulic fluid leaks and minimizes downtime, maintenance and part contamination. Electric linear actuators are critical for productivity, providing consistent reliability in high duty cycle applications.

Tolomatic offers a full range of electric designs with various screw drive technologies to provide solutions for every axis of motion on molding and automation equipment. Built to order and built to last, our planetary roller screw actuators provide the ultimate in high speed, high force and responsive performance in a compact profile. Application solutions include:

- Injection molding — Mold positioning, core pull, gate valve control, part ejection

- Plastic thermoforming — Extrusion, die positioning

- Blow molding — Mold positioning, clamping

- Ultrasonic welding

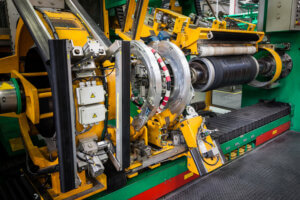

Electric Linear Actuators for Rubber Product Manufacturing

Hydraulics have traditionally been the source of linear motion in rubber product production. However, eliminating hydraulic leaks with electric linear actuators translates to reduced production costs via improved productivity, accuracy, product quality and manufacturing floor safety. Consistent high duty cycle reliability of Tolomatic electric actuators means improved uptime and lower maintenance costs. Control capabilities of electric linear actuators enable linear motion optimization opportunities on virtually every axis impacting production.

For tire manufacturing, there are applications for electric linear actuators — both rod style and rodless designs — throughout the production process. A few examples:

- Material lifting conveyors

- Rubber cutting

- Product feeding

- Tire turn up

- Green tire transfer

- Tire inspection processes

- Gantry system diverting & sorting

Our application engineering team is experienced in linear motion solutions for plastic and rubber product manufacturing processes. Let’s optimize your processes together. Start the conversation: Ask an Engineer

Product Family: Electric

Product Used: MXB belt drive actuator

Challenge: Automated bagging of empty molded bottles for transporting

Product Family: Electric

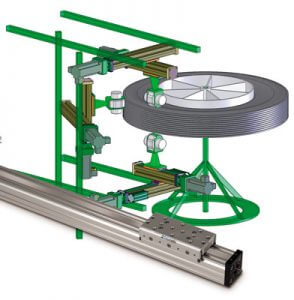

Product Used: B3W Linear Belt-Drive Actuators

Challenge: Rubber cutting in automotive tire manufacturing.

Product Family: Electric

Product Used: MXB Belt-Drive Electric Rodless Actuators

Challenge: Product feeding in automotive tire manufacturing.

Product Family: Electric

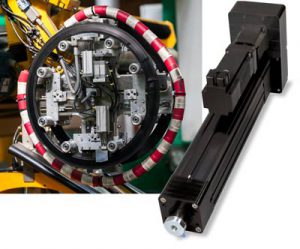

Product Used: RSA32 Screw-Drive Electric Rod-Style Actuators

Challenge: Turn up fabric reinforced and gum plies around the bead of the green (raw) tire

Product Family: Electric

Product Used: RSA64 Screw-Drive Electric Rod-Style Actuators

Challenge: Transferring tire in & out of curing station during automotive tire manufacturing

Product Family: Electric

Product Used: RSA32 Screw-Drive Electric Rod-Style Actuators

Challenge: Material reclamation from used tires for use in automotive tire manufacturing

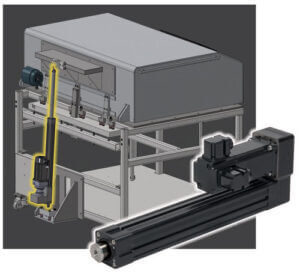

Product Family: Electric

Product Used: GSA24 Guided Rod-Style Screw-Drive Electric Actuators

Challenge: Precise positioning of product, blowers, sealers, welders, and more.

Product Family: Electric

Product Used: IMA Integrated Motor Actuator

Challenge: Directing product to secondary conveyor line.

Product Family: RSA Rod-Style Screw Drive Actuator

Product Used: RSA32

Challenge: Diverting and sorting various size auto and truck tires during manufacturing.

Product Family: Pneumatic

Product Used: MXP63P Rodless Band Cylinder with Profiled Rail Bearing

Challenge: Indexing tires for verification by a camera system during the manufacturing process.

Product Family: Electric

Product Used: MXB63P Profiled Rail, Belt-Drive Electric Rodless Actuator

Challenge: Replace hydraulics in a tire inspection press

Product Family: Electric

Product Used: RSX15 Extreme Force Rod-Style Electric Actuator

Challenge: Laser measurement and inspection during tire manufacturing.

Product Family: Electric

Product Used: MXE25S Rodless Screw Drive Electric Actuator with Solid Bearing

Application Description

Open and close door on a clam shell vacuum sealer used for plastics thermoforming.

Challenge: Positioning a plastic welding head.

Product Family: Electric

Product Used: RSA Electric Linear Actuator

Challenge: An injection molding OEM was struggling with long lead times from their existing electric actuator supplier.

Product Family: IMA Integrated Motor Actuator

Product Used: IMA

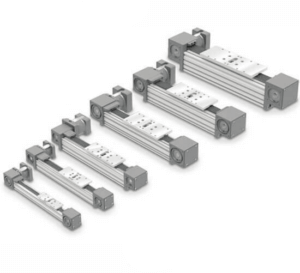

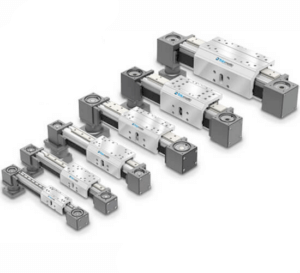

Belt driven actuator is designed for applications where loads are externally guided and supported and high speeds are required. Forces up to 420 lbf (1.9 kN).

Linear actuator that uses a profiled rail bearing and belt drive train to move heavy loads at high speeds. Loads up to 1,290 lbs (586 kg).

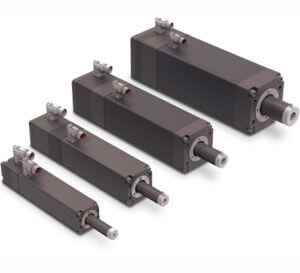

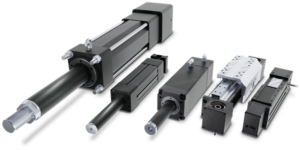

RSA electric linear rod actuators feature accurate and high force performance, making them ideal for replacing pneumatic & hydraulic cylinders. These electric linear actuators feature acme, ball or roller screw selections, with enhanced high thrust bearings and heavy duty internal bumpers. A rigid, strong aluminum housing allows for easy mounting of switches and sensors. RSA actuators are suitable for general motion control, valve actuation, punch press, injection molding and many more applications.

B3W linear belt drive actuators have an enclosed ball bearing design for heavy loads, high bending moments, and long service life.

Electric rod actuator integrated with a servo motor in a single, compact design that integrates with 3rd party drives and accessories. Forces up to 8,044 lbf (35.8 kN).

Ask an Engineer

Ask an Engineer