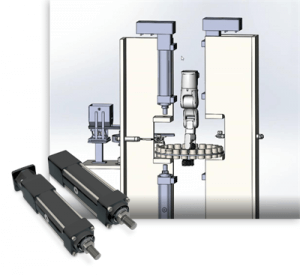

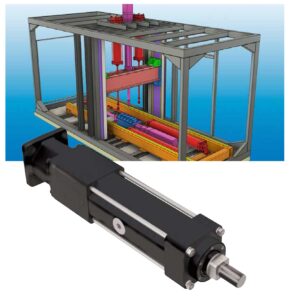

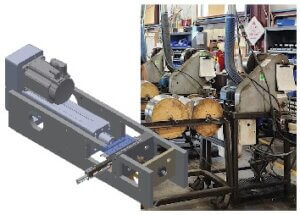

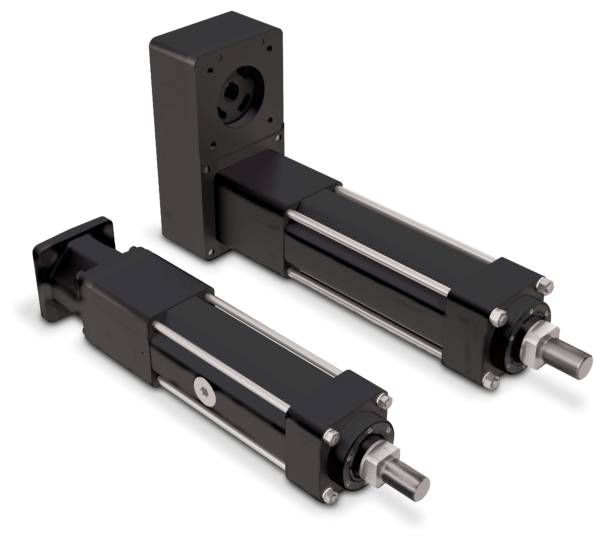

RSX High Force Electric Linear Actuators

Replace hydraulics to eliminate messy leaks and increase system performance

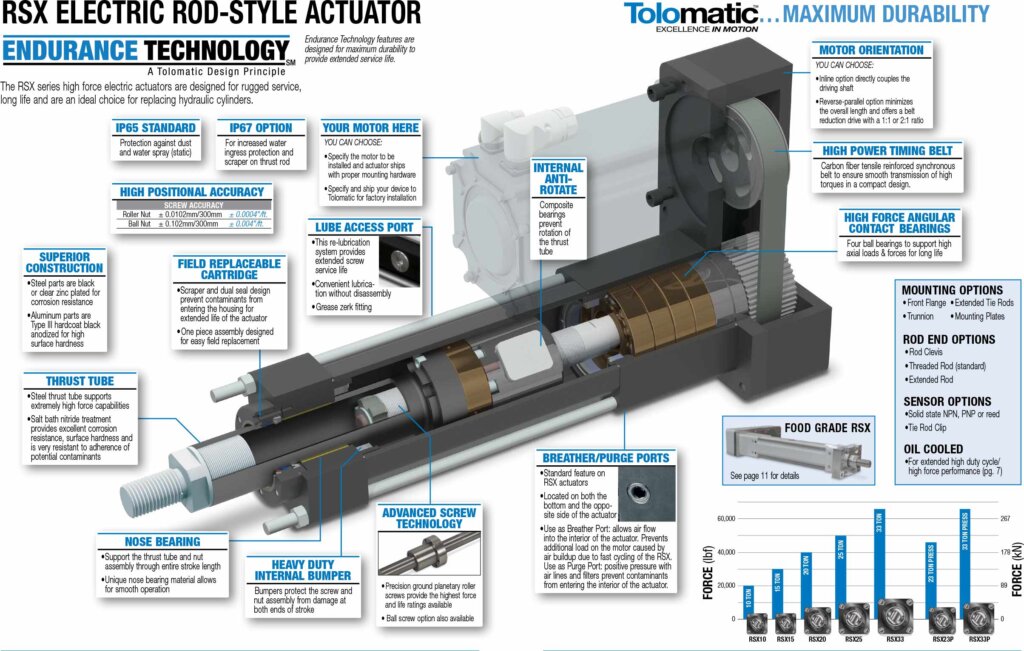

The RSX family of extreme high force electric linear actuators are an excellent alternative to hydraulic cylinders. They’re more efficient, more precise and rugged enough to perform in demanding conditions. Their long life and precision is achieved through the use of Tolomatic’s high precision planetary roller screws.

- Forces up to 66,000 lbf (294 kN)

- Stroke lengths up to 59 inches (1,500 mm)

- Available in Ball and Planetary roller screw driven designs to fit the needs of your application.

- Type III hard coat anodized aluminum housing to withstand demanding environments

- IP67 option to protect against dust and water ingress

NOTE: With recent name change, RSX096 has been renamed RSX15 and RSX128 has been renamed RSX25

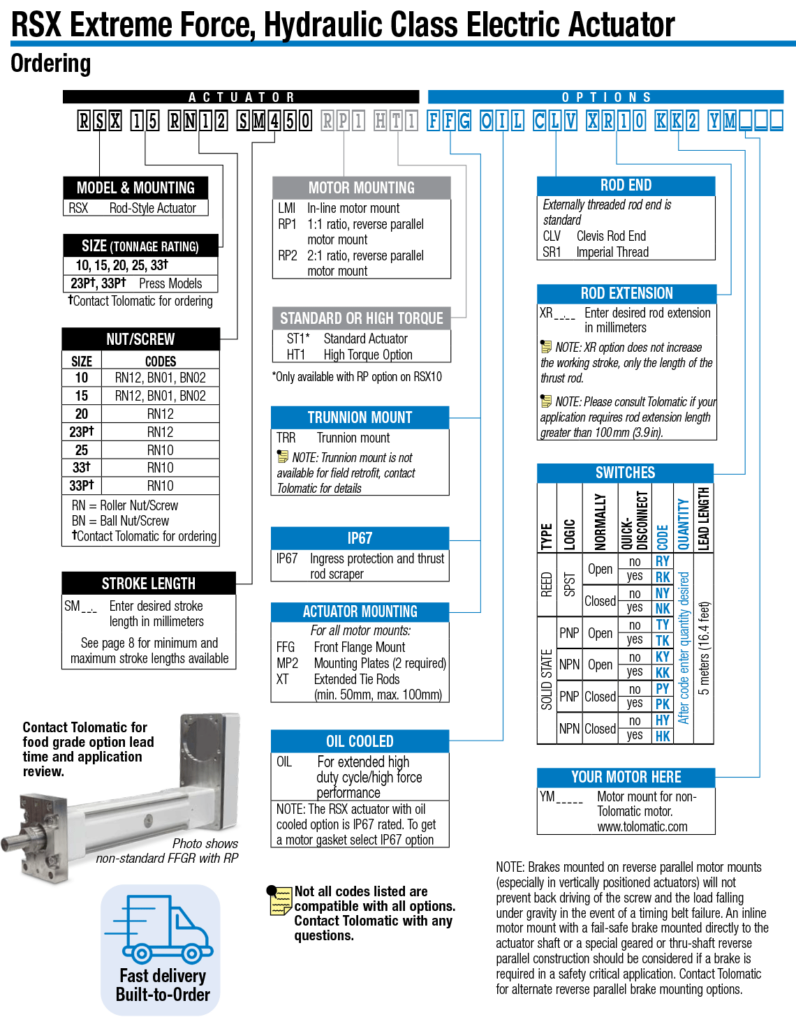

Features & Ordering

Download the RSX Brochure for full details on features

RSX Features

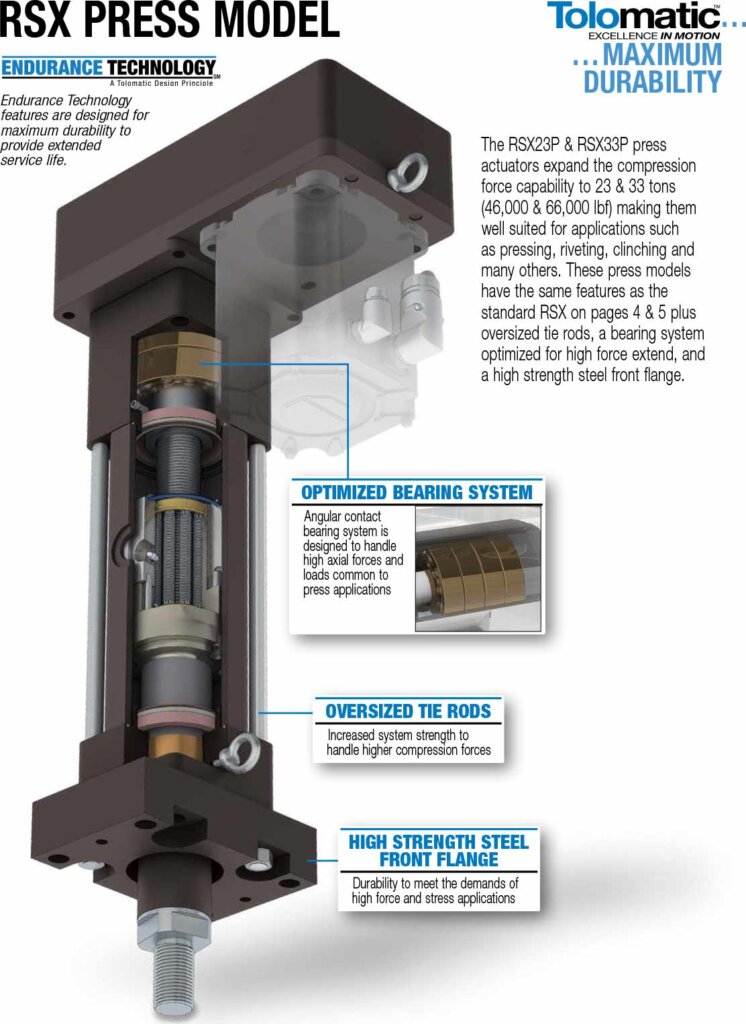

RSX Press Features

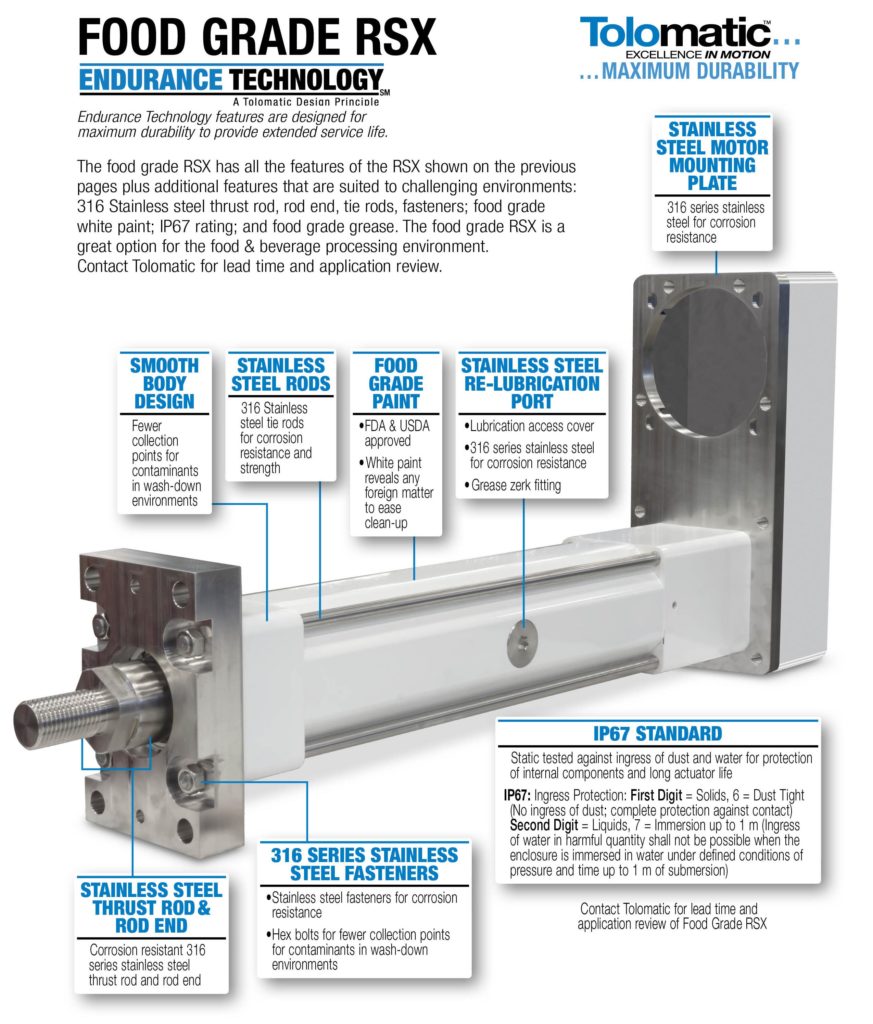

RSX White Paint Features

Ordering - RSX

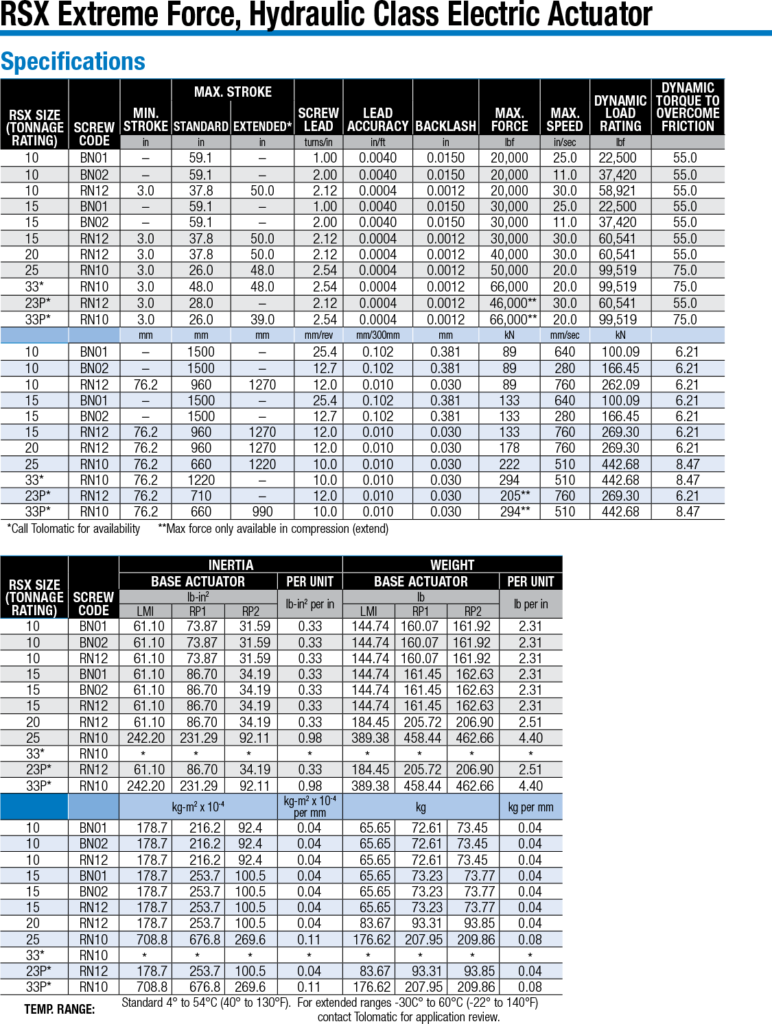

Specifications

| Size | RSX10 | RSX15 | RSX20 | RSX25 | RSX33* | RSX23P* | RSX33P* |

|---|---|---|---|---|---|---|---|

| US Conv. | 59 in | 59 in | 50 in | 48 in | 48 in | 28 in | 39 in |

| Metric | 1,500 mm | 1,500 mm | 1,270 mm | 1,220 mm | 1,220 mm | 710 mm | 990 mm |

*Extended linear actuator stroke lengths may require longer lead times. If you’re unsure about how this would apply to your high force application, contact the Tolomatic engineering team.

| Size | RSX10 | RSX15 | RSX20 | RSX25 | RSX33* | RSX23P* | RSX33P* |

|---|---|---|---|---|---|---|---|

| US Conv. | 20,000 lbf | 30,000 lbf | 40,000 lbf | 50,000 lbf | 66,000 lbf | 46,000 lbf** | 66,000 lbf** |

| Metric | 89 kN | 133 kN | 178 kN | 222 kN | 294 kN | 205 kN** | 294 kN** |

**Max. force only in extend

| Size | RSX10 | RSX15 | RSX20 | RSX25 | RSX33* | RSX23P* | RSX33P* |

|---|---|---|---|---|---|---|---|

| US Conv. | 30 in/sec | 30 in/sec | 30 in/sec | 30 in/sec | 20 in/sec | 30 in/sec | 20 in/sec |

| Metric | 760 mm/sec | 760 mm/sec | 760 mm/sec | 760 mm/sec | 510 mm/sec | 760 mm/sec | 510 mm/sec |

RSX Product Specification

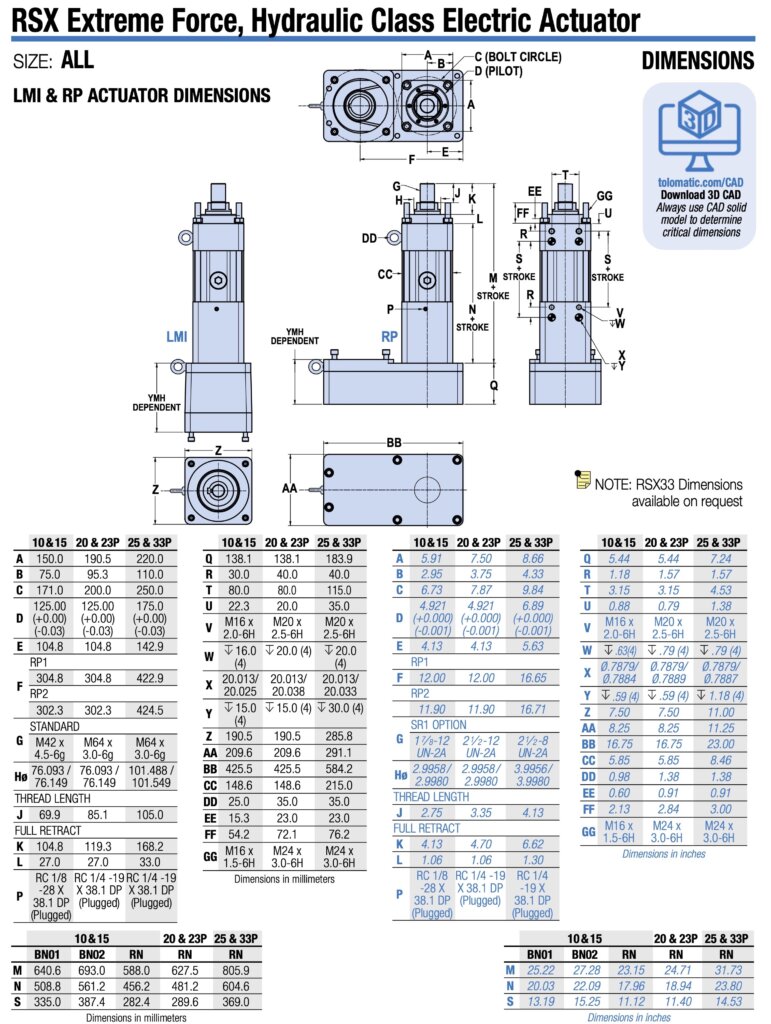

Dimensions

RSX Dimensions

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

English

Chinese

German

Spanish

Application Checklists

- Electric Rod-Style Actuator Application Checklist

- _HOJA DE TRABAJO - DATOS DE APLICACIÓN (Electric Rod-Style Actuator Application Checklist-Spanish Translation)

- _FICHE TECHNIQUE DES DONNÉES D'APPLICATION (Electric Rod-Style Actuator Application Checklist-French Translation)

- _FOGLIO DI LAVORO - DATI APPLICATVI (Electric Rod-Style Actuator Application Checklist-Italian Translation)

- Anwendungsdatenarbeitsblatt (Electric Rod-Style Actuator Application Checklist-German)

- Hydraulic Cylinder Replacement Worksheet

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- 公司概述 (Chinese, Corporate Overview Brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- RSX Extreme Force Electric Linear Actuator Brochure

- RSX Fuerza Extrema Actuator Eléctrico – Catálogo (RSX Actuator brochure, Spanish)

- Elektrischer RSX Linearantrieb mit extremer Kraft – Broschüre (RSX Actuator brochure, German)

- Automotive Applications Brochure

- Aplicaciounes de la Ind. Automotriz (Auto Appl SP)

- 汽车行业应用手册 Brochure (Chinese: Automotive Applications Brochure)

- Electric Pressing Solutions Brochure

- OEM Actuator Solutions Brochure

Certifications

E-Books

Flyers

- RSX Oil Cooled Extreme Force Actuator

- RSX Extreme Kraft, Elektrische Antriebe der Hydraulikklasse Flugblatt (RSX Flyer, German)

- RSX Extreme Force Electric Linear Actuator - Flyer

- RSX ACTUADORES ELÉCTRICOS DE FUERZA EXTREMA PARA REEMPLAZO HIDRÁULICO (Spanish - RSX, Extreme Force, Hydraulic Replacement Rod Style Actuator)

- RSX Servo Motors & Drives - Nidec

Guides

- INFOGRAPHIC: Electric vs. Servo-hydraulic vs. Hydraulic Actuators

- INFOGRAPHIC: Pneumatic, traditional electric, and integrated electric rod actuators

- Rod Style Roller Screw Actuator Comparison

- A Guide to Converting Hydraulics to Electric Actuators

- Abschnitt: Welches Gewinde? Die richtige Technologie auswählen (German - Which Screw)

- Guide to Third Party Motor Integration

- Switch Reference Guide

- Guía para Conversión de Actuadores Hidráulicos a Eléctricos

Tech Bulletins

Terms & Conditions

Videos

White Papers

- Electric Rod Actuators vs. Hydraulic Cylinders: A Comparison

- High-force linear motion: How to convert from hydraulic cylinders to electric actuators and why.

- A technical comparison: Performance of pneumatic cylinders and electric rod actuators

- Electric actuator technology comparison: Integrated and traditional designs

- Utilizzo degli attuatori elettrici nelle applicazioni di processo (WP: IT: Actuators for F&B processing applications)

- How roller-screw and ball-screw actuators compare in high-force applications:

- Actuadores eléctricos con vástago frente a cilindros hidráulicos: una comparación de los pros y los contras de cada tecnología (Spanish - White paper - Electric vs Hydraulic Actuators)

- Top 5 best practices for designing electric actuators into food processing equipment

- Elektrische Antriebe und Pneumatikzylinder: Ein Vergleich basierend auf den Gesamtbetriebskosten weißes Papier (GERMAN, TCO WhitePaper)

- Elektrische Stangenantriebe vs. Hydraulikzylinder: Ein Vergleich der Vor- und Nachteile beider Technologien weißes Papier (GERMAN, Electric vs Hydraulic WP)

- Designing Gantry and Multi-Axis Automation Systems

- Diez Consejos Óptimos: Cómo especificar los actuadores eléctricos de vástago para obtener rendimiento, confiabilidad y eficiencia óptimos

- Integrierte und traditionelle Bauweisen Weißbuch (DE, Integrated and traditional designs WP)

- Unleashing the Capabilities of the Linear Servo Press in Manufacturing

- Liberar las Capacidades de la Servoprensa Lineal en la Fabricación

- Making the Jump to Electric

Ask an Engineer

Ask an Engineer