Roller Screw Actuators Give Linear Servo Presses an Advantage in High-Force Applications

By John Fenske on July 25, 2024

In our previous blog post in this series, we provided an overview of how servo-electric presses are replacing hydraulic machines in high-force applications. Continuing the discussion, let’s look at linear servo press actuation methods and how planetary roller screw actuators are enabling this technology.

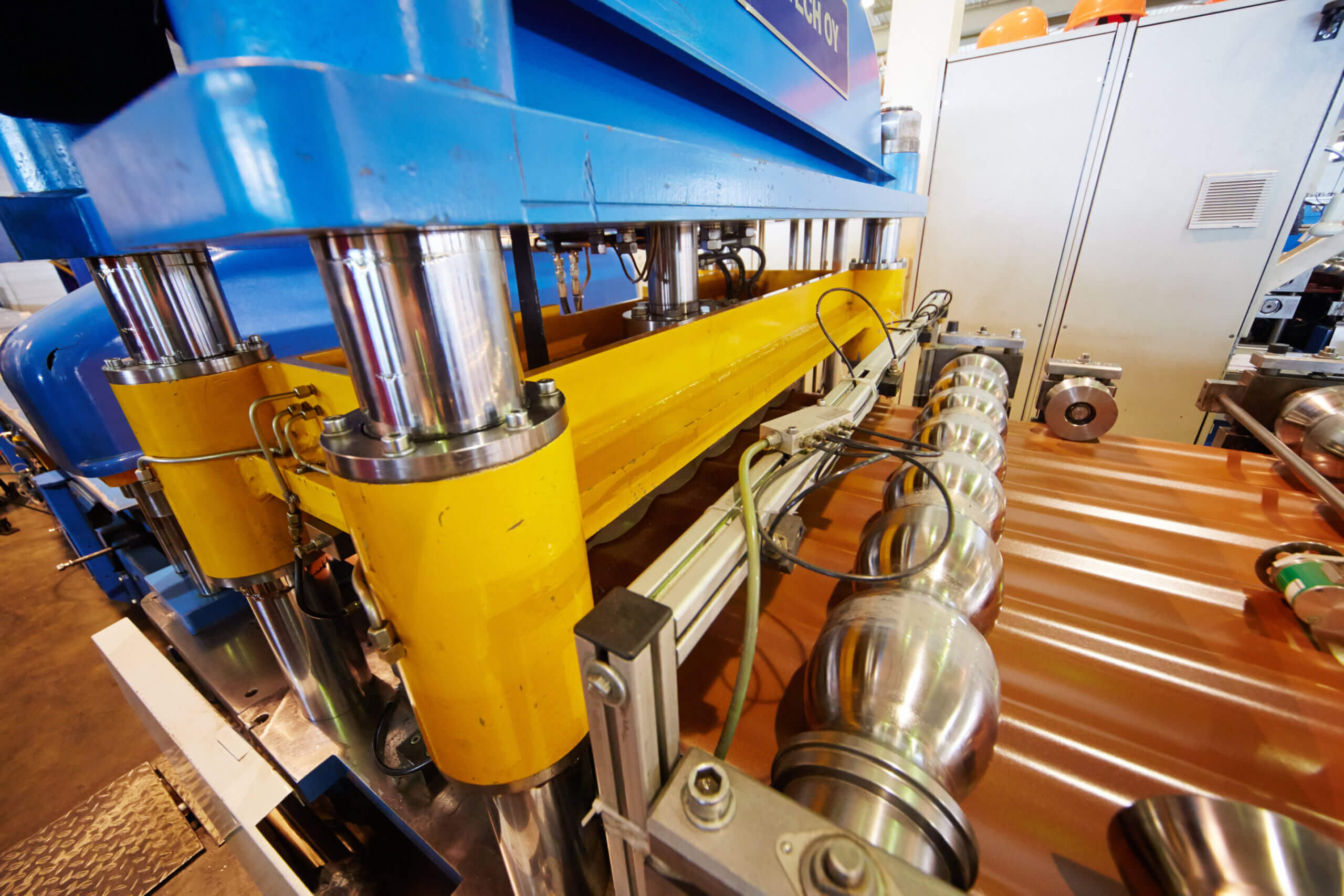

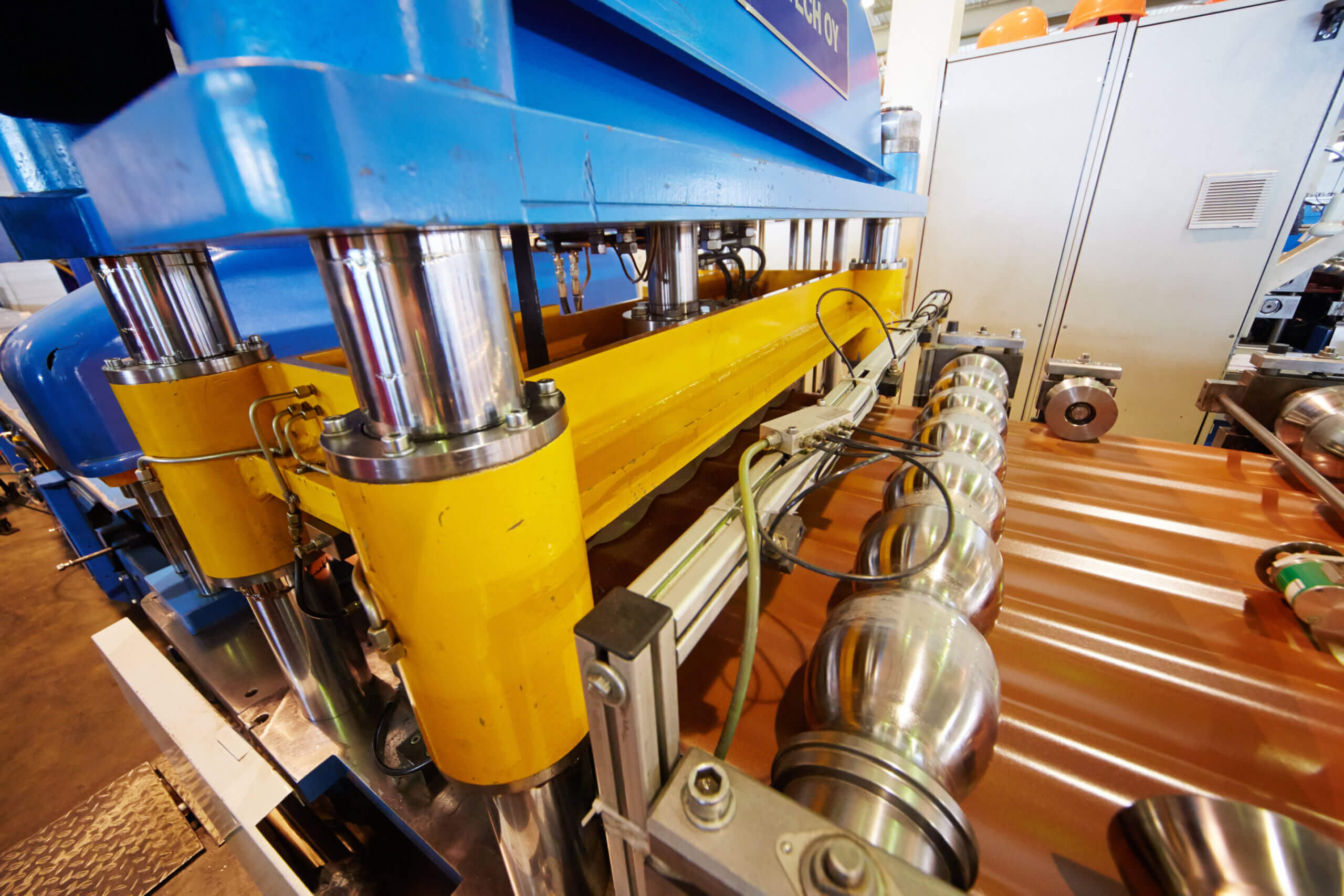

Most linear servo presses use rod-style linear actuators to convert rotary motion into linear motion. In a linear servo press, the type of rod-style actuator determines overall performance, reliability and lifespan. For these press applications, ball screw and roller screw designs are most common, each offering its own advantages.

Ball Screw Actuation

Ball screw actuators consist of a circular-toothed screw. Multiple ball bearings fit into the circular grooves and are housed inside a nut assembly. These ball bearings recirculate throughout the assembly and transmit rotary force into linear force. The ball bearings cannot be manufactured below a minimum size and they feature a coarse pitch, which limits the number of contact points between the screw and bearings. Because there are fewer points of contact within the ball screw assembly, the forces acting on each ball bearing are greater, reducing maximum load capabilities and lifespan.

This decrease in lifespan — known as the actuator’s dynamic load rating (DLR) — represents the constant load that a ball bearing or power screw device can withstand over 1,000,000 revolutions of rated life while maintaining 90% reliability. In other words, higher actuator DLR contributes to higher forces and longer service life.

Because they often feature lower DLR values than roller screw actuators, ball screws are better suited for moderate loads with less stringent reliability and service life requirements.

Planetary Roller Screw Actuation

Planetary roller screw actuators consist of a precision-ground screw that matches a set of precision-ground threaded rollers. Compared to their ball bearing counterparts, the rollers provide many more points of contact and a larger contact radius. This design lowers the stress on each point of contact and enables roller screws to carry heavier loads.

The planetary roller screw design also reaches higher DLR values, further increasing reliability, precision and life span. Roller screw actuators are more compact than ball screw designs. Because they meet higher force requirements than ball screws, roller screws allow for smaller, lighter and more flexible machine designs.

Design Considerations

To ensure optimal performance when specifying an actuator for a linear servo press, design engineers should consider force and load requirements, as well as the sizes, speeds, accuracy and duty cycles necessary for success. Here are some additional considerations to keep in mind:

- Control system compatibility

- Positioning repeatability

- Environmental and safety factors

- Maintenance requirements

- Energy and cost efficiency

Learn More

While both ball screws and roller screws have their advantages, roller screws are key to linear servo presses meeting extremely high force requirements. Keep in mind that each application is unique and that it is always beneficial to speak with an actuator application expert.

Contact us or read our brochure to learn more.