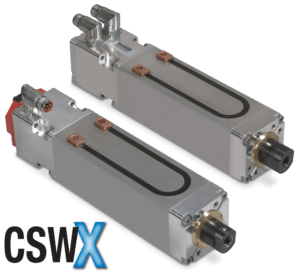

ServoWeld® Compact Spot Welding Actuator

ServoWeld® servo actuators are used in resistance spot welding for robotic applications. By combining servo motor technology with a powerful high-force actuator for a compact profile and faster weld cycles, these are purpose-built for automotive body-in-white resistance spot welding applications.

Find products by model or keyword

ServoWeld® Actuators

Narrow your choices

Integrated servo motor/actuator used in robotic resistance spot welding which offers a compact, power dense actuator solution with best-in-class performance. Forces up to 4,050lbf (18kN).

Integrated servo motor and rod style spot welding actuators offer a cost-effective design with solid performance. Forces up to 4,950lbf (22.0kN).

Design that combines an electric rod actuator with guide rods, mounting blocks, and bearings. Ideal for applications requiring guidance and support of the load. Forces up to 950 lbf (4.2 kN).

Integrated spot welding actuators offering a spot welding solution for forces up to 3,300 lbf (14.7kN).

Where Do ServoWeld® Actuators Perform Best?

Compact servo actuators are commonly used for resistance spot welding applications due to their reliability and force repeatability. Servo actuators play a crucial role in controlling the movement and force applied during resistance spot welding, offer greater control in applications such as electronics, aerospace and automotive manufacturing.

What are the factors of weld performance optimized by Tolomatic servo actuators?

Tolomatic’s ServoWeld actuators are designed for best-in-class performance with the factors that are most important for resistance spot welding gun applications.

- Number of welds(product life): Tolomatic’s roller screw design has the highest dynamic load rating for more welds than competitive technologies like other roller screws, ball screws or pneumatics.

- Force repeatability: Tolomatic’s unique motor design minimizes motor cogging and provides highly repeatable actuator force – ±3% over the lifetime of the actuator.

- Efficiency: All elements of actuator (winding, screw, rod scraper, bearings) are designed to provide the most energy efficient solution on the market.

- Welds per minute: All elements of the actuator are designed for long life and to run as cool as possible in welding applications.

- Weight: Tolomatic integrated servo actuators minimize weight when designed into the weldgun. Additionally, Tolomatic can customize actuators for specific weldgun applications to provide industry leading light weight designs.

- Lifetime cost: By optimizing long life, efficiency and welds per minute, Tolomatic actuators provide the lowest total cost per spot weld.

Why Tolomatic Actuators?

Tolomatic actuators are designed in the U.S. and built to deliver both the force and precision needed for unique applications in a wide variety of industries.

Have questions about which of our products is the best choice for your particular application? Talk to our engineers.

Can’t Find What You’re Looking For?

We offer a wide selection of high-quality, long-lasting electric linear actuators. Designed to offer clean, continuous control and reduced cycle times for a variety of applications — including industrial and high speed — you can browse additional options here.

Ask an Engineer

Ask an Engineer